Product Brand

Flowserve Type

Mechanical Seals SubType

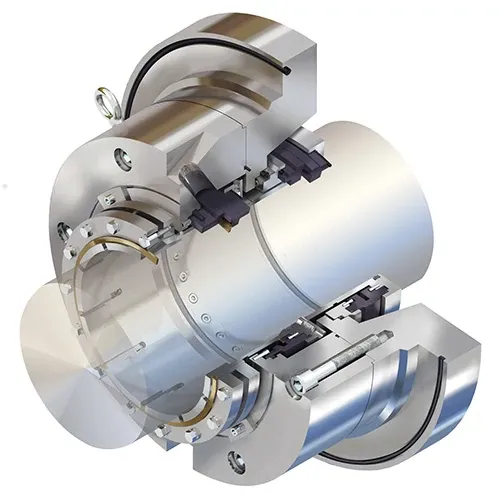

Slurry Seals- No process bypass or external flush liquid is needed, eliminating product dilution for better chemical stability. This increases product pumpage to raise production and reduce the operating expense of complicated packing or seal water support systems.

- Cartridge seal configuration makes installation and operation easier. Allows for equipment impeller-to-casing clearance adjustments without making modifications to the seal setting.

Up to 17.2 bar (250 psi), -18 to 79°C (175°F), up to 23 m/s (75 fps)

6000

Single, balanced, multi-spring, pusher cartridge slurry seal

6200

Dual, balanced, multi-spring, pusher cartridge slurry seal

Online Tools