Desalination

As global demand for clean water accelerates, Flowserve's innovative desalination solutions are providing fresh water to communities around the world.

Integrated systems and services that reduce total cost of ownership

In designing modern desalination plants, cost-effective water production, energy consumption and system availability are major drivers. Our ability to deliver complete, integrated flow control systems that are energy-efficient and scalable enables desalination plants to operate economically and grow with demand.

Regardless of the desalination process, Flowserve supports customers with specialty equipment and aftermarket services to advance plant operating goals and keep key flow control processes running smoothly.

Flowserve offers:

- Unparalleled experience in the design and operation of high-efficiency fluid motion and control systems.

- Single point of contact and responsibility for all major equipment, including pumps, energy recovery devices, valves and mechanical seals.

- Equipment and system optimization to provide the lowest total cost solution.

- Engineering and technical resources for application support and ongoing life cycle cost-reduction services.

- Local support of parts, repairs and service through nearly 200 global Quick Response Centers.

- Condition monitoring and maintenance contracts that guarantee availability and efficiency of equipment.

- Educational services that train customer personnel in the selection, operation and maintenance of pumps, energy recovery devices, seals and valves.

Reverse osmosis desalination

Energy consumption is generally the biggest operating cost driver of RO desalination. Advances in membrane and energy recovery technologies are making SWRO and brackish water reverse osmosis (BWRO) more economical, but it can’t be taken for granted.

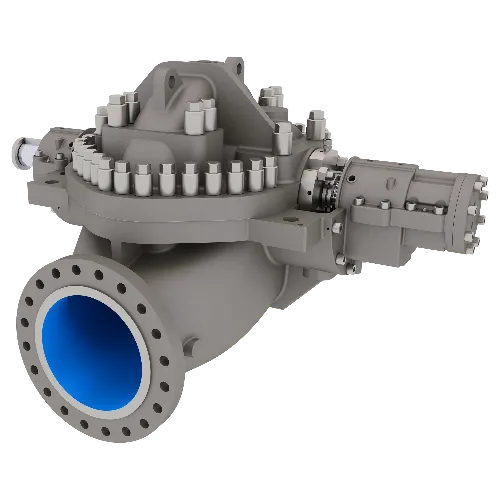

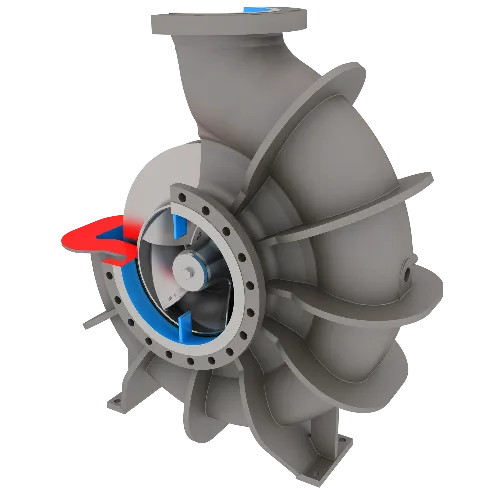

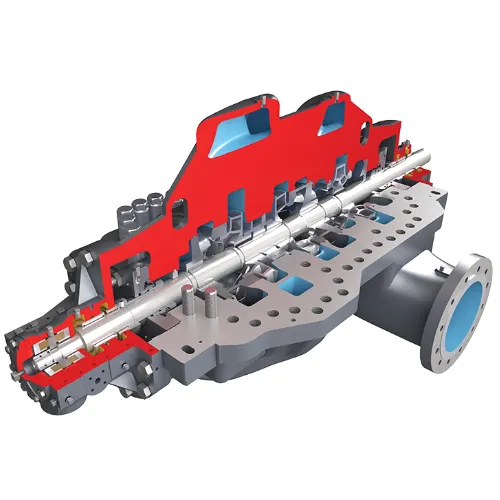

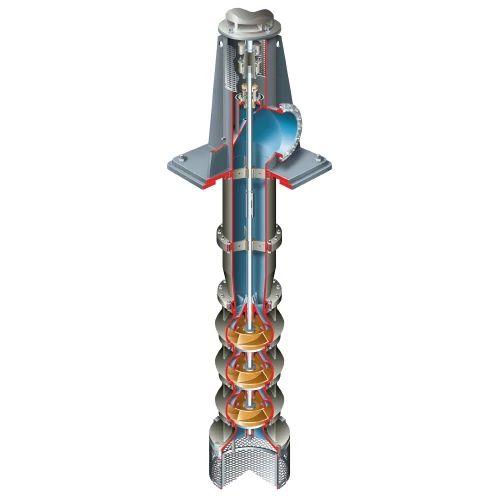

We understand RO plants consume a lot of power, much of it by high pressure pumps, so we build optimal efficiency into every one of our RO systems. Our high-pressure membrane feed pumps and ERDs — including Flowserve FLEX™, Calder® DWEER™ isobaric devices and Calder ERT energy recovery turbines — feature optimized hydraulics and advanced material technologies to keep operating costs low and plants running profitably. Moreover, our detailed systems knowledge along with a full menu of technical support services are available wherever and whenever needed to ensure plant availability goals are met.

Multistage flash distillation (MSF) and multi-effect distillation (MED)

Thermal desalination via MSF or MED is most economically advantageous where water salinity is very high. Selecting equipment and materials that can survive elevated brine temperatures and salinity is critical to the success of these plants. Pitting, crevice corrosion and stress corrosion cracking are major challenges in processing seawater and brackish water.

Flowserve is unmatched in materials expertise and applications know-how. Our pumps and valves are available in a broad range of corrosion-resistant materials — both metallic and non-metallic — to provide a competitive total cost solution for the corrosive services found in MSF and MED desalination plants.

Providing solutions around the world

Spanish desalination plant recovers energy, reduces costs

The Las Palmas III seawater reverse osmosis (SWRO) plant in the Canary Islands installed seven Flowserve FLEX™ isobaric energy recovery devices (ERDs) in 2022, contributing to significant savings for operating costs and capital expenditures. FLEX pressure exchangers can recover more than 98% of hydraulic energy of the brine stream. With only four major internal parts, the simple design of the FLEX ERD ensures high reliability and uptime with low maintenance costs. The FLEX ERD boasts the highest unit capacity of any pressure exchanger in the market.

Pumping a reliable supply of clean water in Saudi Arabia

The Rabigh 3 IWP seawater reverse osmosis (SWRO) desalination plant in Western Saudi Arabia is one of the world’s largest, with an initial capacity of 600,000 m3/d that can be upgraded to 1.2 million m3/d. Flowserve supplied 60 pumps for a broad range of processes throughout the plant, including booster, second pass, clean-in-place (CIP) and energy recovery applications. Flowserve also provided mechanical seals, motors, supervision services and spare parts. The successful implementation of Flowserve equipment supports the efficient, reliable and sustainable desalination plant, which serves the Jeddah and Mecca areas.

Efficiently meeting Singapore’s drinking water needs

Singapore produces 136 million liters of drinking water per day at its Tuas Desalination Plant 3. The facility opened in 2018 and is the third Seawater Reverse Osmosis (SWRO) desalination plant operated by PUB (Public Utilities Board). RO plants are expected to meet up to 30% of the nation’s water demand. Flowserve provided 50 highly efficient pumps used in processes that deliver the highest output of drinking water per square meter of any of the country’s desalination plants. Among the world’s most space-efficient and technologically advanced desalination facilities, Tuas 3 was honored with the title of Desalination Plant of the Year in 2019.

Essential equipment for world’s largest desalination plant in UAE

With a capacity of 909,200 m3 per day, the Al Taweelah IWP desalination plant in Abu Dhabi, UAE, is the world’s largest Seawater Reverse Osmosis (SWRO) facility. Flowserve delivered a range of essential equipment, including 52 high-pressure (HP), HP booster, Energy Recovery Device (ERD) booster, second pass and clean-in-place (CIP) process pumps. Flowserve also provided mechanical seals, motors, supervision services and spare parts, ensuring smooth and efficient plant operation. Flowserve’s selections for this significant undertaking highlight our expertise and dedication to delivering high-quality solutions for large-scale SWRO projects.

Understanding the business of desalination

We’ve worked with government-backed fixed engineering, procurement and commissioning (EPC) projects as well as privately financed build-own operate (BOO) and build-own-operate-transfer (BOOT) ventures. Our dedicated desalination experts and project managers understand the business challenges of each commercial model.

For new projects or major upgrades, our dedicated global project managers and engineering experts help streamline execution. They offer a total solution approach, focused on creating the most efficient and technologically advanced systems. They work with your teams to select equipment, maximize overall efficiency, and optimize plant layout. And, they also work tirelessly to ensure installation and commissioning meet requirements and schedules.

For existing operations, we’ve invested in aftermarket services and supporting infrastructure to help plant operators manage risks. Our turnkey maintenance contracts guarantee minimum efficiencies of key equipment. Monitoring and preventative maintenance service plans make sure plant availability and throughput goals are achieved.

A complete, integrated flow control system

By bringing together industry-leading pumps and valves, high-efficiency ERDs, unmatched materials expertise and desalination-specific application knowledge, Flowserve is a single-source provider of complete, integrated flow control systems for desalination plants around the world.

Having equipped water desalination plants for more than a half-century, we have the equipment and system expertise to meet these challenges.

Our RedRaven digital water solutions provide the predictive analytics to operate water processes at peak efficiency. With a complete view of equipment performance and predictive maintenance capabilities, digital water processes can be more reliable and cost efficient.

Innovative 3D models for product recommendations

Based on use cases from customers who have successfully used our desalination products, we developed a unique tool that features 3D models of various plant types to help you see our capabilities and browse product information.

Visit our VirtualPlant for Desalination and zoom into the unit level and then to the product level to learn more about the superior desalination equipment, systems and technical support available from Flowserve.

Desalination Application Solution Guide

As global demand for fresh water keeps growing, Flowserve helps desalination plant operators meet capacity objectives with integrated flow control systems that are energy-efficient and scalable.

RedRaven Resolves Water Supply Challenge

A public water supplier was facing losses and fines due to outages. Flowserve’s RedRaven preventive maintenance solution helped bring them back online with streamlined maintenance protocols.

Blogs

Related Products

Let’s discuss your needs

Contact Us