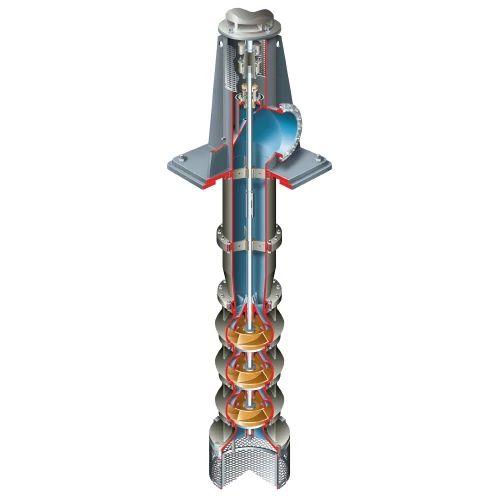

The Flowserve VTP vertical turbine pump is a diffuser-type, single or multistage design for continuous service in wet pit and deep well applications. With more than 250 models available, Flowserve VTP pumps are one of the world’s most comprehensive lines of mixed-flow, vertical turbine pumps. Multiple design configurations and broad hydraulic coverage ensure you get a cost-effective solution that precisely meets your application requirements.

Legacy brands include:

- Worthington

- IDP

- Byron Jackson

- Western Land Roller

VTP pumps are available in a wide variety of configurations, constructions and materials to suit application requirements. Among the options are:

- Standard and ISO 13709/API 610 (VS1), latest edition configurations

- Open or enclosed lineshaft construction

- Enclosed or semi-open impellers, keyed or collet mounted

- Bowl and enclosed impeller wear rings

- Cast iron or fabricated steel discharge heads

- Sealing configurations for open lineshaft construction

- Packed box with flexible graphite packing

- Single or dual mechanical seal

- Sealing configurations for enclosed lineshaft construction

- Enclosing tube tension assembly for oil lubrication

- Water injection packing assembly

- Above ground or below ground discharge flanges

- Multiple drivers

- Electric motors, solid or hollow shaft

- Engines with right angle gear drives

- Steam turbines

- Separate axial thrust bearing assembly

- NSF61-G Certified

- Short Coupled

- Flowserve

- Hydraulic Institute

- AWWA E103

- ISO 13709 / API 610

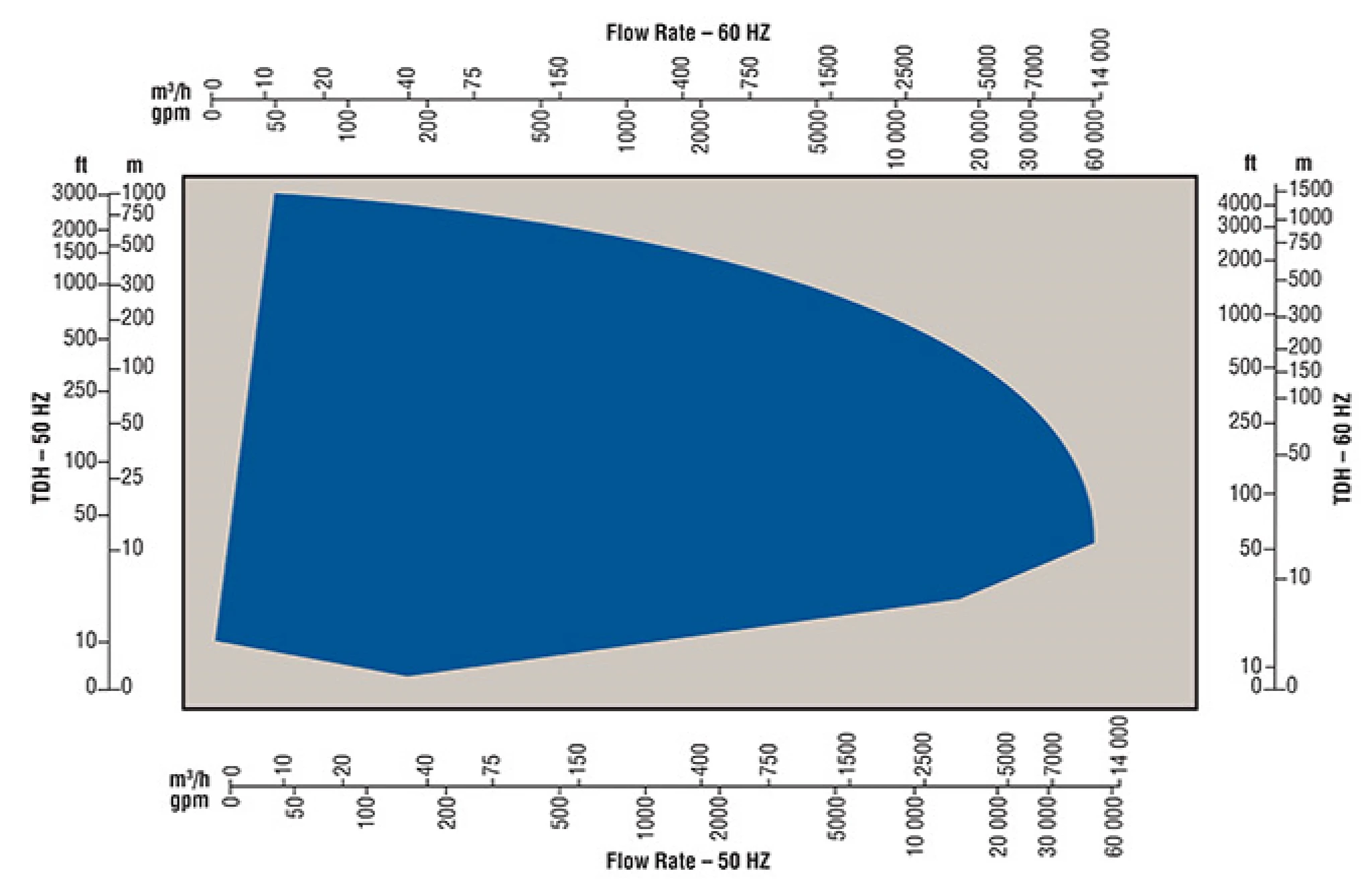

- Flows to 13,600 m3/h (60,000 gpm)

- Heads to 700 m (2,300 ft)

- Pressures to 100 bar (1,450 psi)

- Temperatures from -45°C (-50°F) to 300°C (570°F)

- Sizes from 150 mm (6 in) to 1,375 mm (55 in)

- Settings to 365 m (1200 ft)

Molten salt applications

A mixture of sodium nitrate (NaNO3) and potassium nitrate (KNO3), molten salt — like that used in concentrated solar power plants — possesses high thermal conductivity, allowing temperatures to reach 600°C (1,100°F). As a leading provider of molten salt pumps for more than 60 years, Flowserve understands the detrimental effects of heat distortion on a vertical pump. That’s why Flowserve engineers utilize advanced thermal mapping software to ensure adequate heat dissipation and mitigate distortion.

ISO 13709/API 610 compliance

VTP pumps are available in a configuration that meets ISO 13709/API 610 standards. They are engineered for easy maintenance, high efficiency and long life in demanding applications found in the oil and gas and related industries. Key features include weld neck flanges; precision pump-to-motor couplings; a one-piece pump shaft; dynamically balanced, keyed, enclosed impellers; pinned wear rings; and API 610 forces and moments.

Barge stripping applications

Specifically designed for transportation barges, the Flowserve Barge Pump continues to be the premier brand used on inland and coastal waterways. It is a vertical self-contained, self-priming unit designed for barge unloading and transfer operations. With the high-efficiency Barge Pump, stripping turnaround times are kept to a minimum. Furthermore, its innovative pollution-prevention design inhibits costly oil and chemical spills.

Groundwater development

For irrigation and agriculture markets, pre-engineered designs, standardized materials and stocked components provide a reliable vertical turbine pump that minimizes price without sacrificing quality or performance.