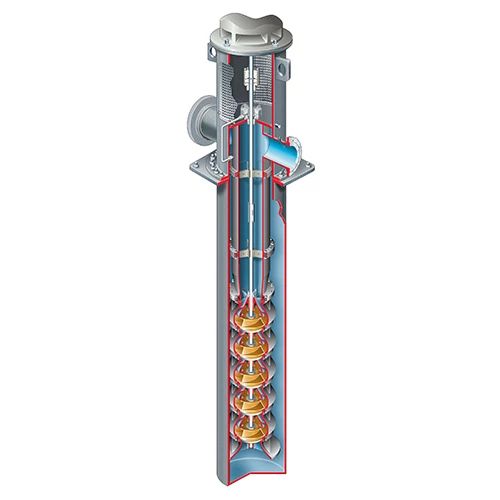

Flowserve VPC pumps are one of the world’s most comprehensive lines of mixed-flow, diffuser-style, double-case vertical turbine pumps. Available in single or multistage construction, as well as standard and ISO 13709/API 610- compliant designs, VPC pumps incorporate the proven hydraulics of the Flowserve VTP vertical turbine, wet-pit pump into a double-casing configuration. They are designed for continuous duty applications and are particularly well suited for services with limited NPSH available. Multiple design configurations and broad hydraulic coverage ensure you get a cost-effective solution that precisely meets your application requirements.

... Read more Read less- Solid shaft motor includes thrust bearing to withstand the total hydraulic thrust as well as the rotor weight

- Rigid, adjustable flanged coupling provides the proper impeller clearance adjustment

- Bowls are designed with multiple diffuser vanes and flanged construction

- Bowl bearings on either side of the impeller provide rigid shaft support

- Enclosed or semi-open impellers are cast to provide smooth passageways for more efficient fluid flow

- Suction bell is designed to provide efficient fluid flow into the eye of the first stage impeller

- Flowserve

- Hydraulic Institute

- AWWA E103

- ISO 13709 / API 610

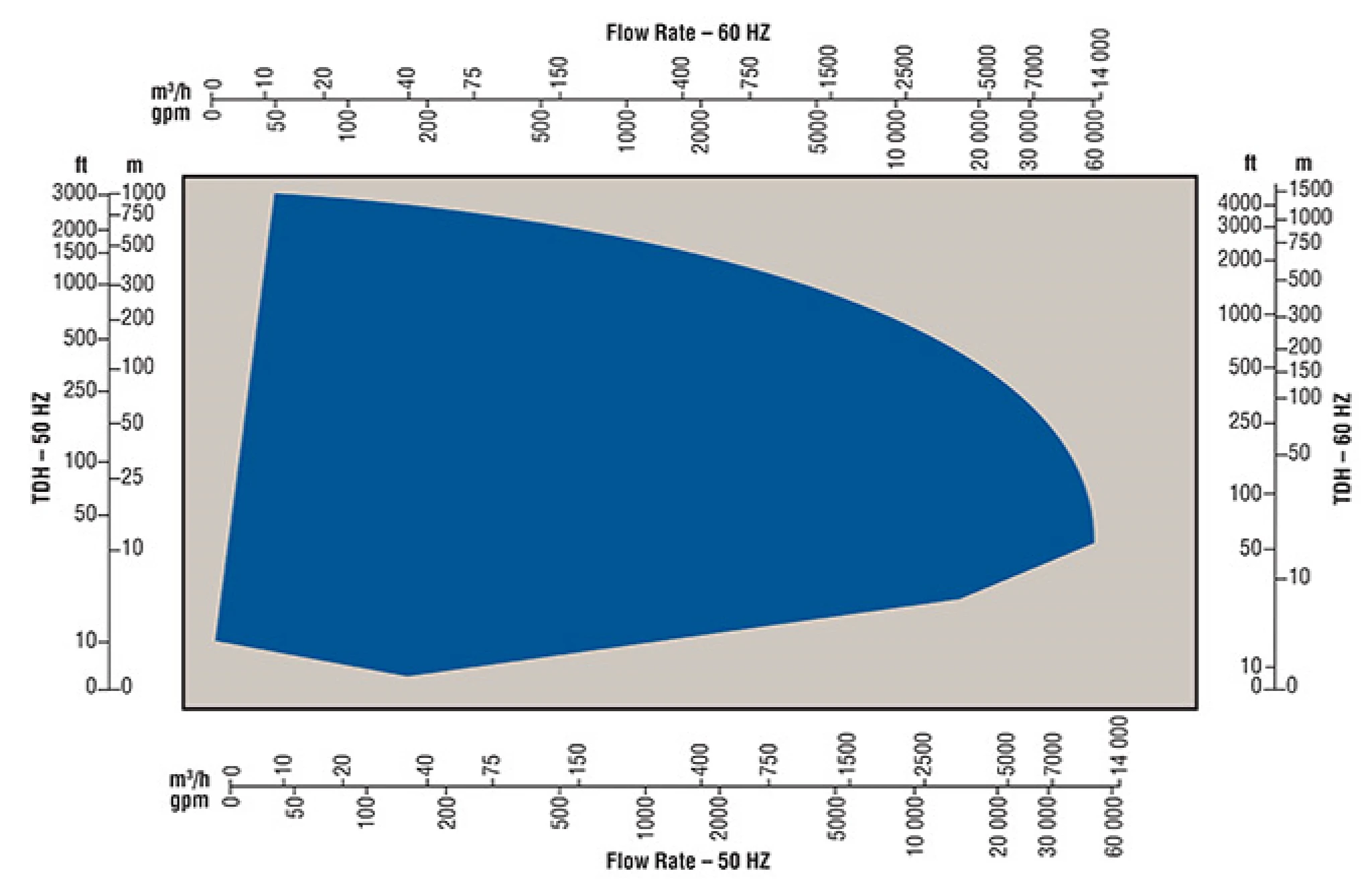

- Flows to 13,600 m3/h (60,000 gpm)

- Heads to 1070 m (3500 ft)

- Pressures to 100 bar (1,450 psi)

- Temperatures from -75°C to 230°C (-100°F to 450°F)

- Sizes from 150 mm (6 in) to 1375 mm (55 in)

VPC pumps are available in a wide variety of configurations, constructions and materials to suit application requirements. Among the options are:

- Standard and ISO 13709/API 610 (VS6), latest edition configurations

- Enclosed or semi-open impellers, keyed or collet mounted

- Bowl and enclosed impeller wear rings

- Fabricated steel discharge head and suction can

- Sealing configurations

- Packed box with flexible graphite packing

- Single- or dual-mechanical seal

- Above- or below-ground suction flanges

- Multiple drivers

- Electric motors, solid or hollow shaft

- Engines with right angle gears

- Steam turbines

- Internal and external suction can drains

- Separate axial thrust bearing assembly

- NSF61-G Certified

- Canned Booster

- Short Coupled