The Durco Mark 3 ISO chemical process pump provides unmatched performance and reliability, conforms to ISO 2858 and ISO 5199 design criteria and incorporates advanced design features. The ruggedly designed Durco Mark 3 ISO offers significant operational and maintenance enhancing benefits that help users to minimize the total cost of pump ownership.

... Read more Read less- High efficiency design with low power consumption

- Modular system resulting in maximum flexibility to adapt to a wide variety of applications

- Extensive hydraulic options available to adapt to different process fluids

- High interchangeability with five casing options on the same power end

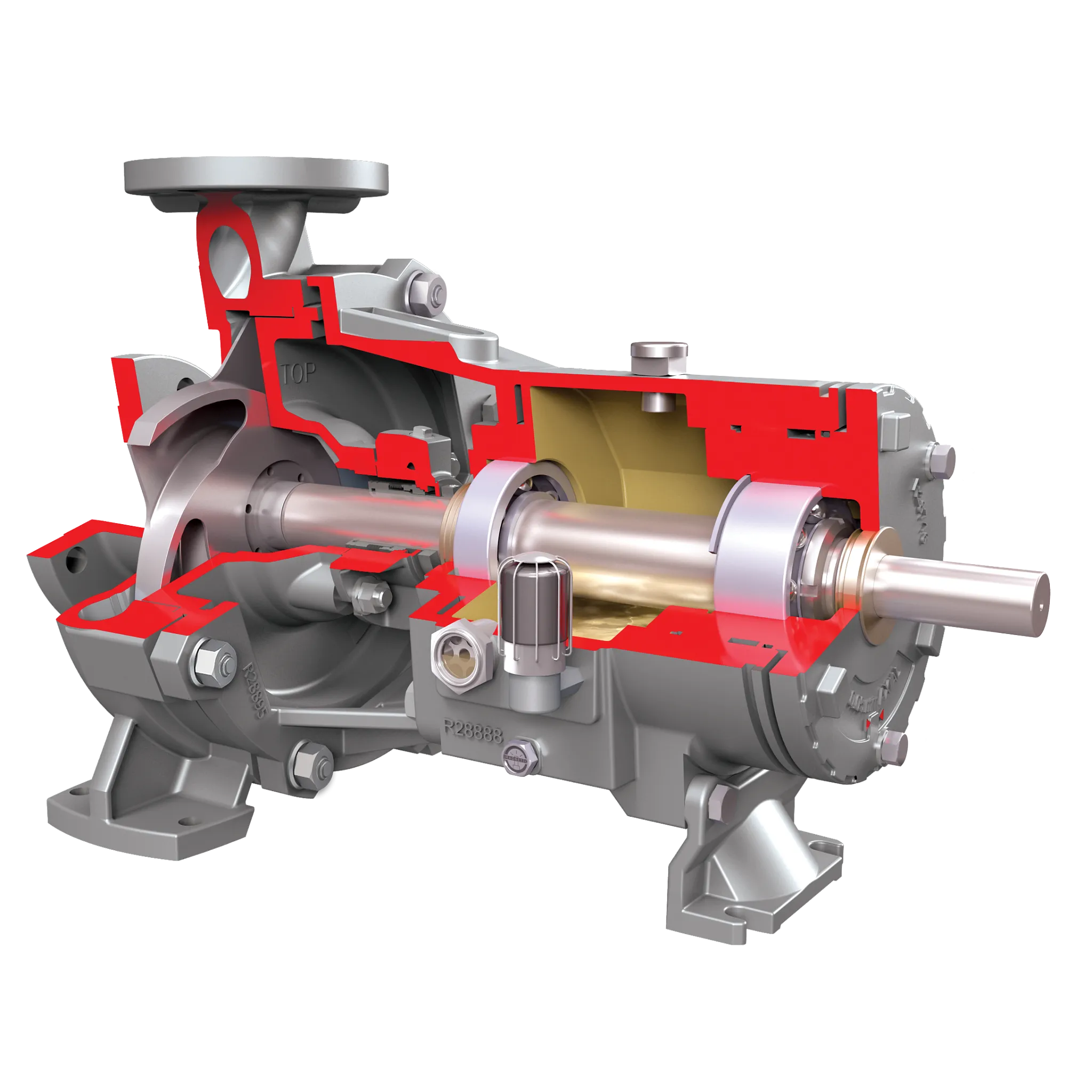

- Four high efficiency impeller options; reverse vane, closed and open impellers available

- Low maintenance costs due to minimal downtime and maximized uptime

- External micrometer impeller adjustment mechanism accurately sets impeller clearance in 20 seconds, in the shop or the field

- Back pull-out design allows removal of rotating element without removing casing, piping or motor

- High environmental and personal safety during operation and maintenance

- Heavy-duty casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads and improves reliability

- Precision cast reverse vane impeller is the only impeller design that offers repeatable pump performance throughout the life of the pump

- SealSentry™ seal chamber extends seal life and provides advanced self-flushing capability

- Standard non-contacting labyrinth seals keep lubricant in and contaminants out

- Heavy-duty radial and thrust bearings selected for long life and reliability

- Two-piece, ductile iron bearing housing is designed for safety, strength, interchangeability and retrofit capability

- 1935/2004/EC food grade compliant option

- ISO 2858

- ISO 5199

- ATEX (2014/34/EU)

- Food grade (1935/2004/EC)

- Drinking water (98/83/EC)

- CUTR

- Flows to 1400 m3/h (6160 gpm)

- Heads to 220 m (720 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -80°C (-110°F) to 400°C (752°F)

Size Range: 20 mm (0.75 in) to 200 mm (8 in)

CK: Closed coupled model provide a compact arrangement ideal for installations where space is a premium.

N: Centerline mounted, high pressure model is available for applications in which loads caused by thermal expansion need to be reduced.

H: Foot-mounted, high pressure model is the workhorse of chemical plants and other industries with a pressure rating up to 25 bar (365 psi).

P: Unitized self-priming model is engineered to draw from liquid sources below ground level or from sources that have no positive pressure to naturally prime the pump.

R: Recessed impeller model uses vortex action to provide low-shear pumping of friable solids and trouble-free pumping of stringy or fibrous slurries.