Product Brand

Flowserve Type

Mechanical Seals SubType

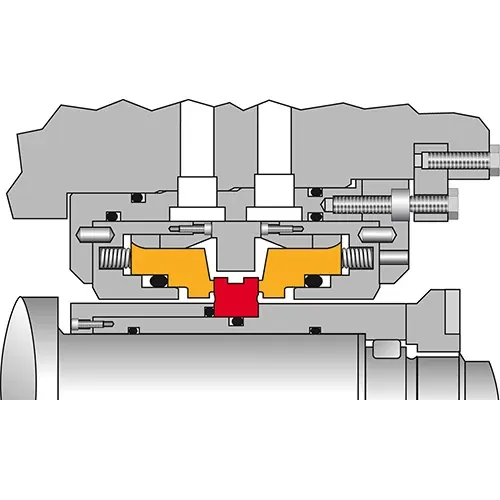

Compressor Seals and Systems- Stationary spring assembly allows higher rotational speed

- Higher safety, efficiency and reduced oil loss from the low leakage rate

- Robust design provides long life and lower life cycle cost

- Dual acting static seal allowing for product containment under reverse pressure conditions

- Available in a cartridge design for simpler installation

- Designed to handle emergency shut downs for added safety

API, ASME others

Up to 300 bar (4300 psi), to 180°C (350°F), up to 100 m/s (19,700 fpm), to 260 mm (to 10.250 inch)

Turbopac 368

Bi-directional Wet Compressor Seal

Turbopac 375

Bi-directional Wet Compressor Seal

Turbopac 2100

Bi-directional Wet Compressor Seal

Online Tools