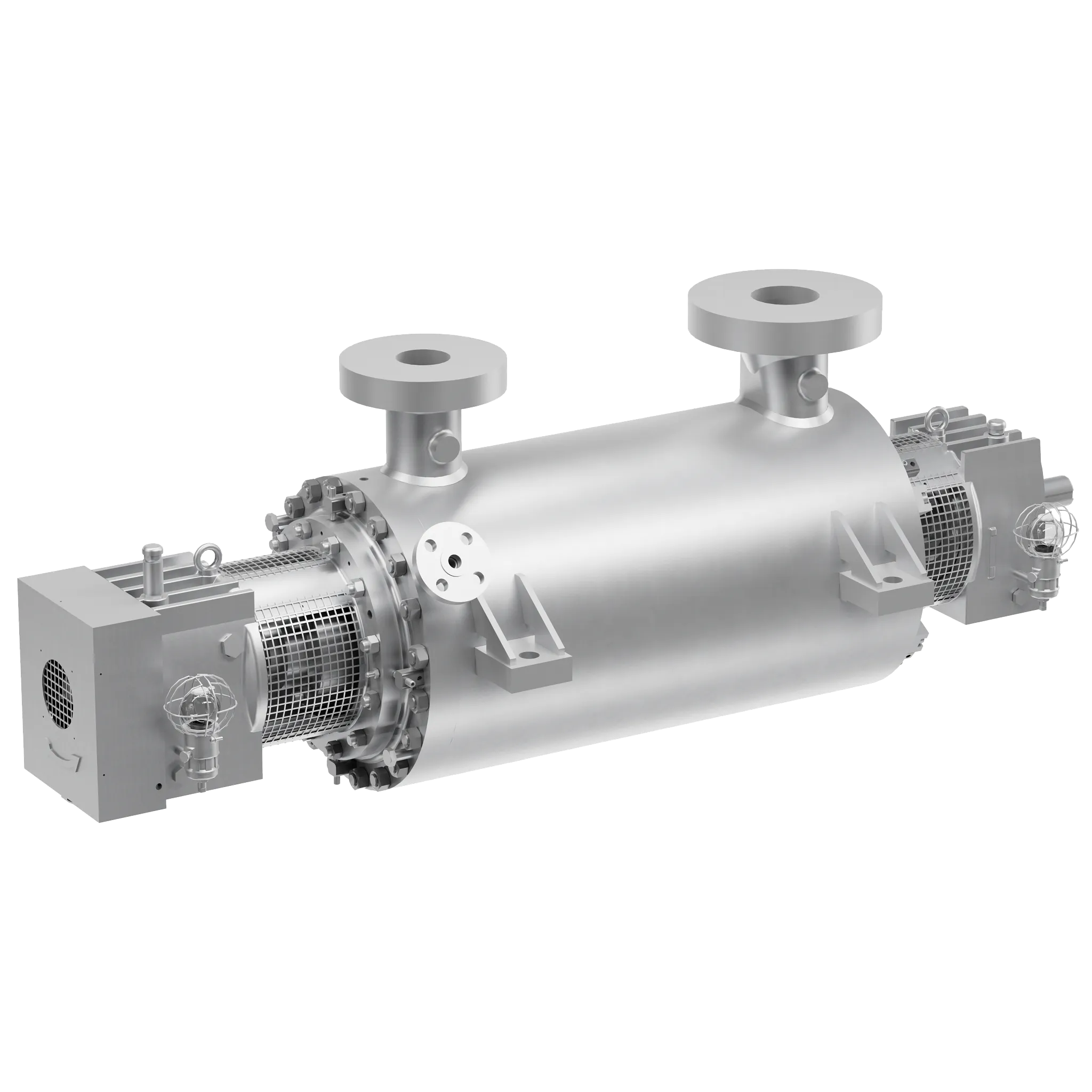

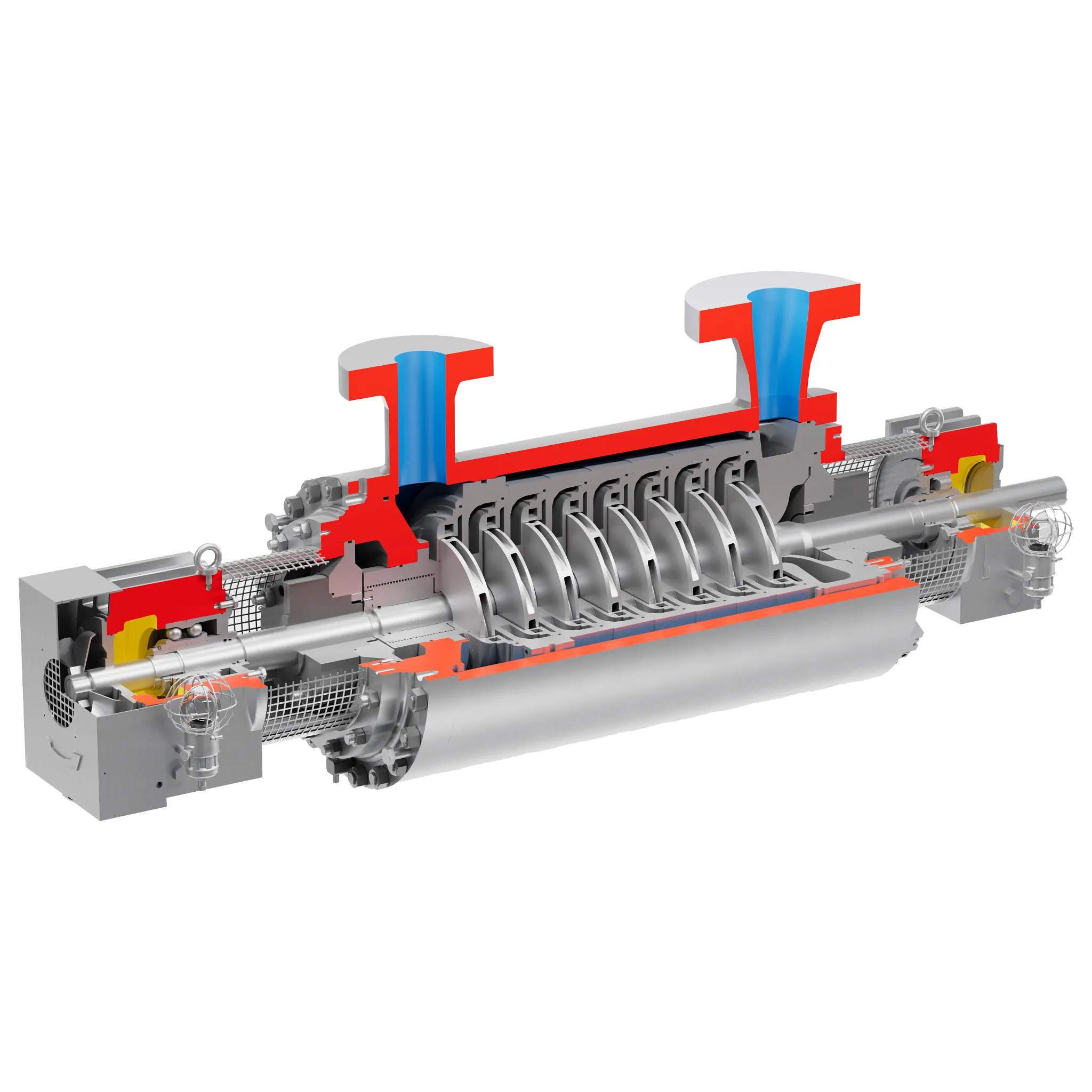

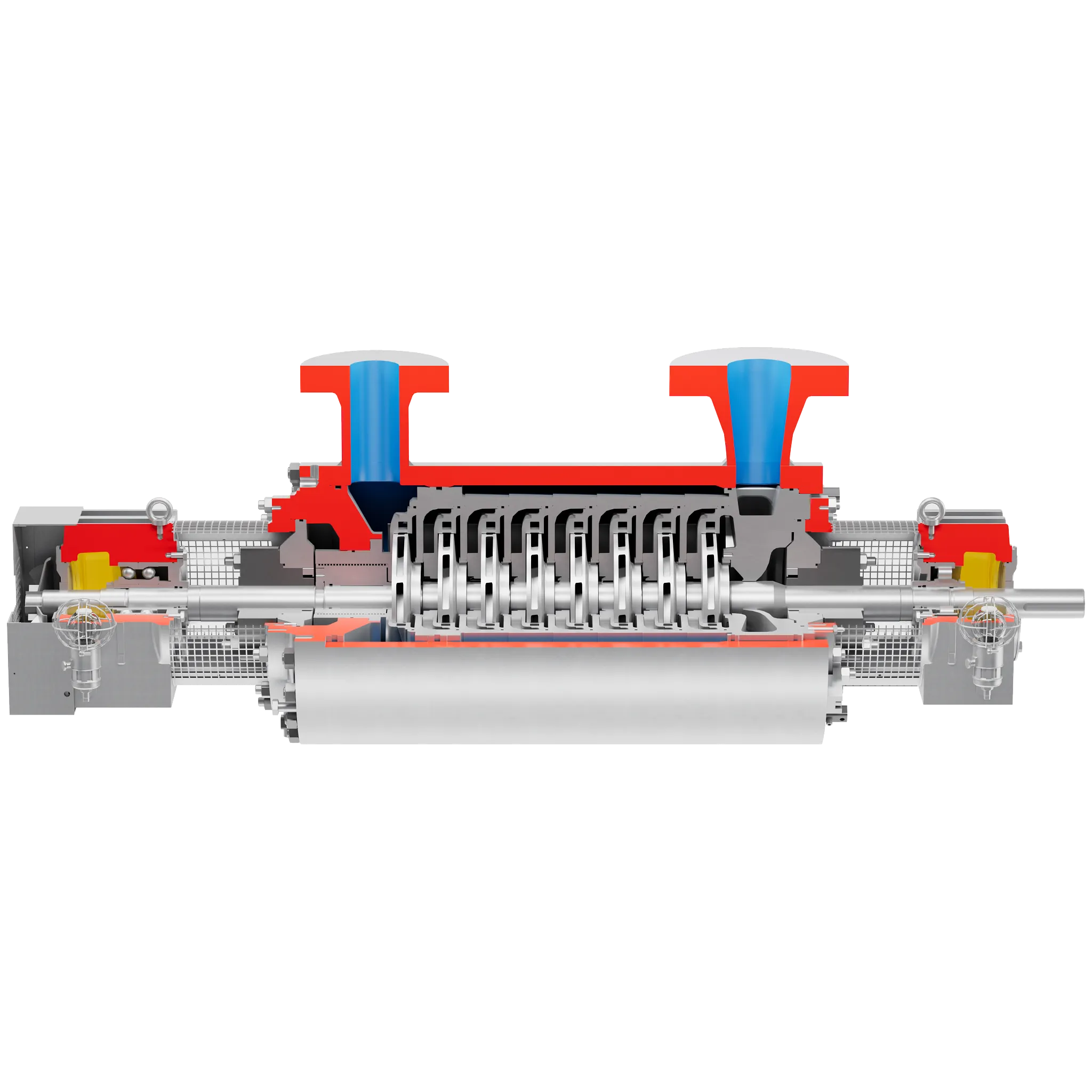

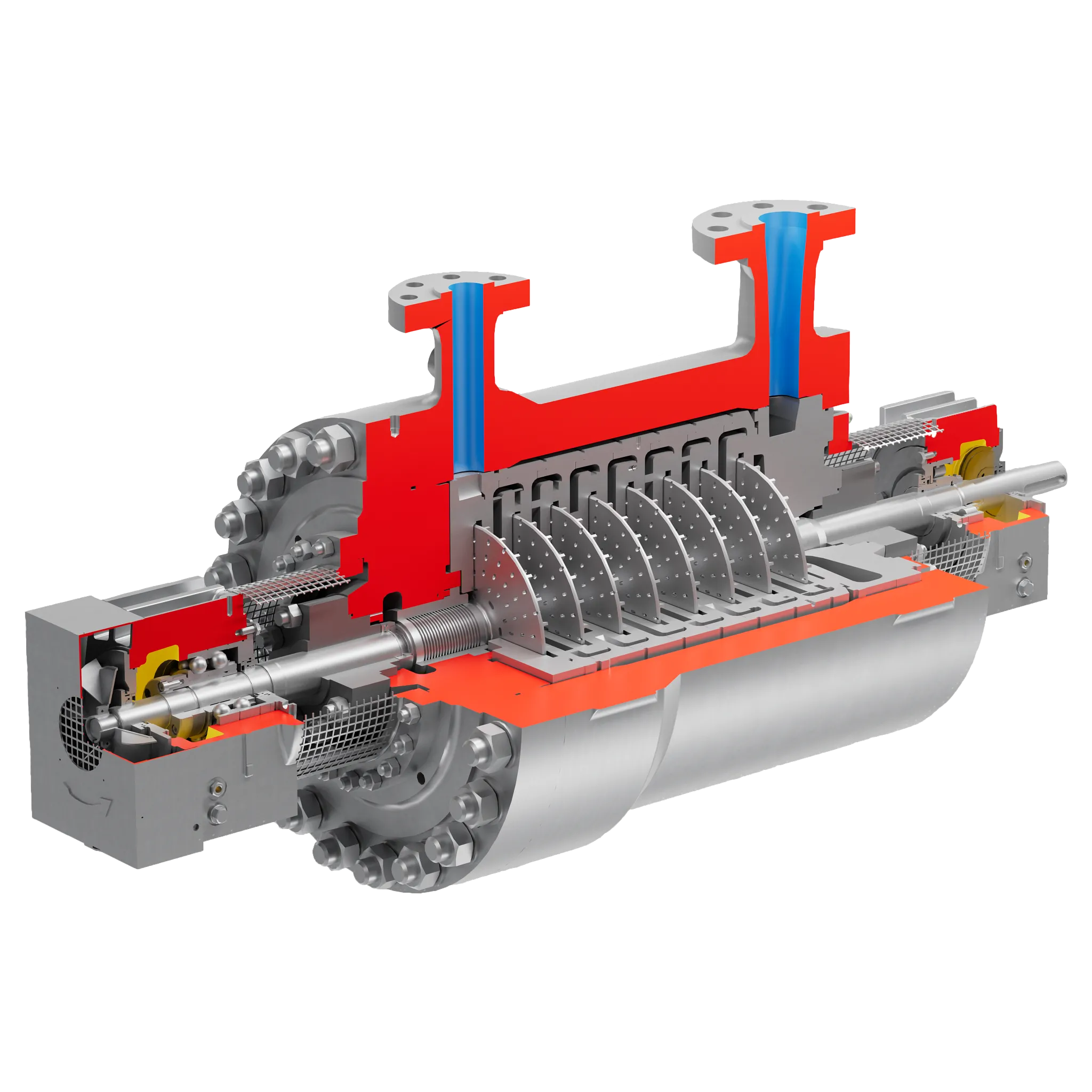

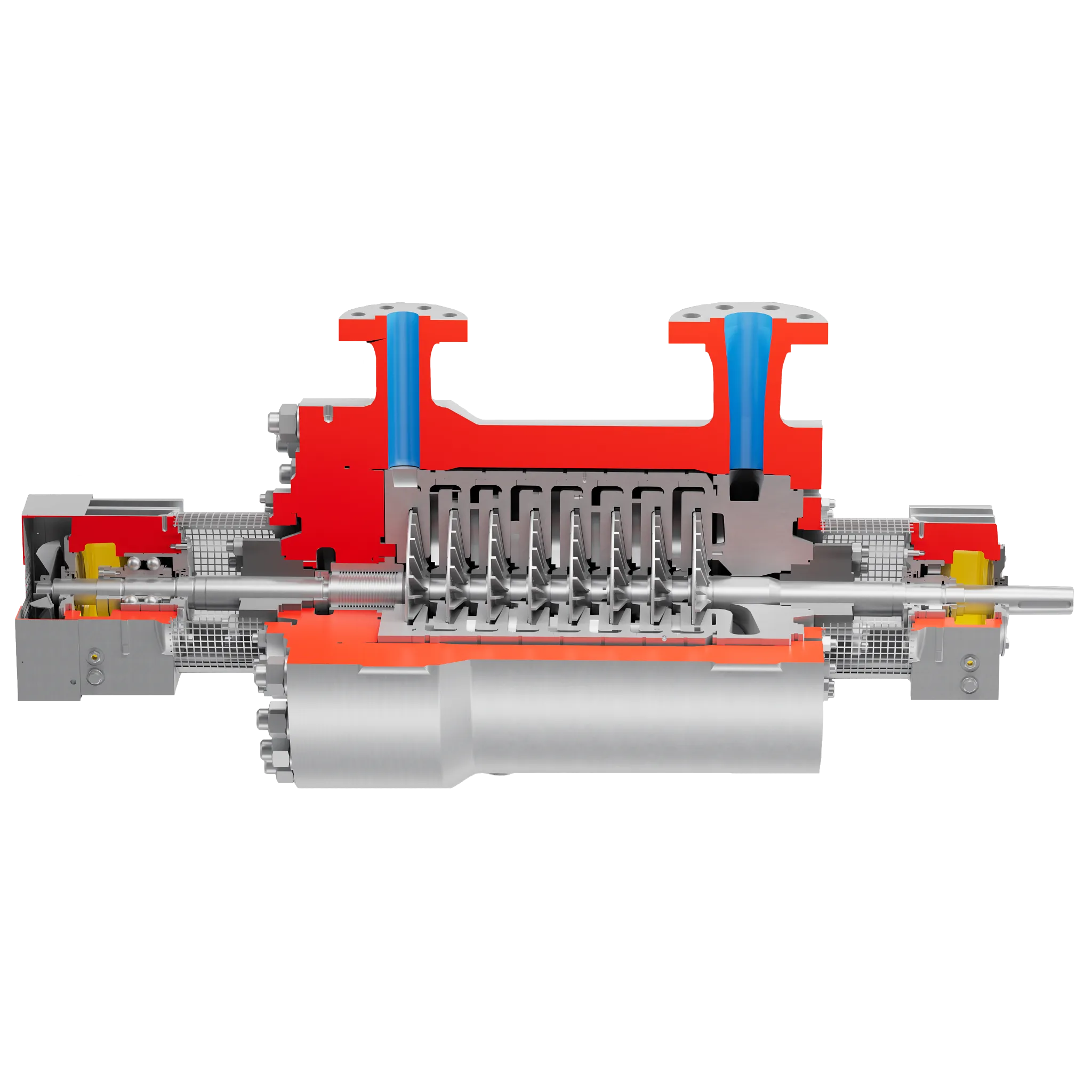

The WXB is a multistage, diffuser-casing barrel pump with tandem impellers and a balance drum to carry axial thrust forces. It is designed for users who need the hydraulic range and performance of a ring section pump, but demand the design and maintenance attributes of a barrel pump. An extension of the well-proven WXB, the WXBB is an API 610-style, multistage barrel pump which incorporates Barske style impellers to produce stable low-flow performance. It is a reliable, direct drive solution for low-flow, high-head applications.

... Read more Read lessDesigned to meet the intent of API 610, latest edition the WXB pump is a BB5 category, double case horizontal, multistage, centerline mounted barrel pump.

The compact, space-saving design has a convenient cartridge-style construction to minimize maintenance down time. The WXB is field proven in oil refineries and petrochemical plants throughout the world and first choice for medium demanding applications - in all services where process conditions demand a barrel construction, process industry, refineries, chemical and petrochemical plants, liquefied gas stations, condensate service and boiler feed service.

A full range of sizes from 2” to 6” combined with a wide range of hydraulics, numbers of stages and all API material columns allows the WXB to be applied across the complete breadth of the market. An on-going research and development program guarantees an up-to-date product, constantly evolving to meet the latest standards API 682 mechanical seal chambers, ASME, ATEX, CE marking etc.

The WXBB pump is a horizontal, double case, diffuser collector, multistage, centerline mounted between bearing pump designed to meet API 610 latest edition requirements. The inner element is constructed as a two piece channel ring/diffuser stage and Barske impellers mounted in-line (tandem), utilizing a straight balance drum at the discharge side to balance residual thrust.

The hydraulics are specifically developed for stable performance in low flow high head applications.

- Flowserve

- Hydraulic Institute

- API 610

- API 682 seal chamber and seal flush plans

- ASME, ATEX, PED

WXB

- Flows to 300 m3/h (1320 gpm)

- Head to 1200 m (3940 ft)

- Pressure to 150 bar (2175 psi) as standard; to 200 bar (2900 psi) on back-to-back configuration

- Temperature from -75°C (-103°F) to 300°C (572°F)

WXBB

- Flows from 4.5 m3/h (20 gpm) to 35 m3/h (154 gpm)

- Heads to 1560 m (5116 ft)

- Pressure to 200 bar (2900 psi)

- Temperature from -46°C (-51°F) to 200°C (392°F)

Size Ranges

WXB

- 4 frame sizes

- 13 hydraulics

- Up to 16 stages

WXBB

- 1 size

- 8 hydraulic designs

- Up to 8 stages

Flowserve Horizontal - Multistage - Double Case - WXB / WXBB

Worthington Horizontal - Multistage - Double Case - WXB / WXBB