Product Brand

Lawrence Pumps® Type

Specialty Products SubType

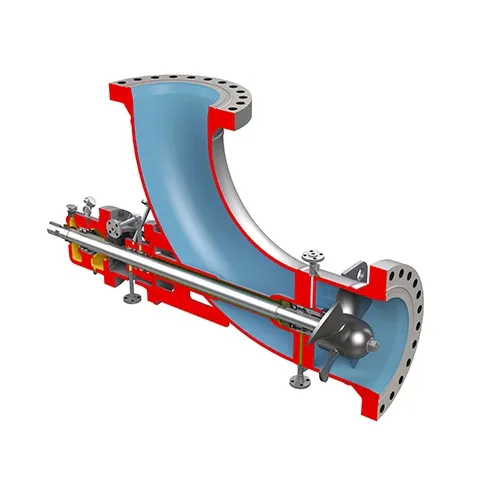

Polyolefin Reactor Pump- High-pressure Elbow Casing is designed, fabricated and tested per ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 and applicable international standards.

- Propellers are engineered with steep pump head curves to ensure process performance requirements are met while allowing superior process control.

- Triple Seal Arrangement is standard on large pumps, providing added safety and increased reliability over alternative designs.

- API Plan 32/53C/52 seal support systems ensure adequate seal face lubrication and cooling for proper operation.

- Other seal arrangements and support systems are also available.

- Internal Anti-friction or Sleeve Bearings are self-aligning and support radial and axial loads.

- Cantilevered shafts are typically utilized on pumps with discharge sizes up to 12 inches.

- Standard Flanges are ASME B16.5 or B16.47, Class 600 weld neck, but alternative ratings and types may be specified.

- Custom flanges are also available.

- Numerous driver types and installation configurations are available to suit site requirements.

- Drive options include: direct, variable speed, cardan shaft and V-belts

- ISO 13709 / API 610

- Flows to 18 180 m3/h (80 000 gpm)

- Pressures to 100 bar (1450 psi)

- Temperatures to 349°C (660°F) (custom designs available for limits exceeding those listed)

Size Range: Sizes from 6" to 36" (custom designs available for limits exceeding those listed)

Online Tools