Flowserve DMX-RO high-efficiency membrane feed pumps are engineered using the latest technologies and materials to provide long-lasting, efficient operation in reverse osmosis applications. The DMX-RO pump is built for high-pressure, heavy-duty membrane feed services used typically in seawater reverse osmosis (SWRO) applications. Hydraulics are designed with advanced computational fluid dynamics (CFD) to provide best system performance and minimize operating expenses. The pump’s comprehensive hydraulic range permits precise selection to deliver best hydraulic fit, operating efficiency and stability, all of which help to extend mean time between repair (MTBR). Corrosion-resistant materials ensure long performance life without degradation.

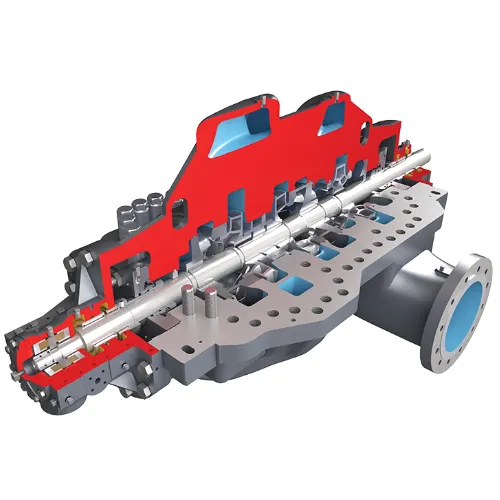

... Read more Read less- Axially split casing design simplifies maintenance and reduces downtime. Pump internals are accessed easily via the top casing, so the bottom casing and piping connections are not disturbed.

- Casing and internal material combinations selected to meet service requirements. Available materials of construction include carbon steel, chromium steel, austenitic stainless steels and super-duplex stainless steels.

- Nozzles are integrated with the lower half casing and designed to handle external forces and moments equal or in excess of ISO/API specified figures.

- Variety of impellers and stage configurations available.

- Cap nuts are arranged on the top half casing parting flange, allowing easy casing removal for rotor inspection and maintenance.

- Axially split center bushing facilitates replacement while simplifying inspection and dynamic balancing of the rotor without dismantling.

- Continuous cross-over design to optimize internal losses, increase efficiency, and support hydraulic balance.

- Double-volute construction supports radial thrust balancing.

- Optimized impeller wear part clearances and careful material selection improve efficiency and maximize mean time between repair.

- Flows to 2,950 m³/h (13,000 gpm)

- Heads to 850 m (2,789 ft)

- Pressures to 90 bar (1,305 psi)

- Temperatures to 50°C (122°F)

- Speeds to 3,600 rpm

Sizes: DN 150 to 300 (6 to 12 in)

Pressure class: PN 90 (1,305 psi)

Materials:

- Super-duplex (A890, Grade 5A; PREN ≥ 40)

- Optional Alloy 885 (PREN ≤ 40)