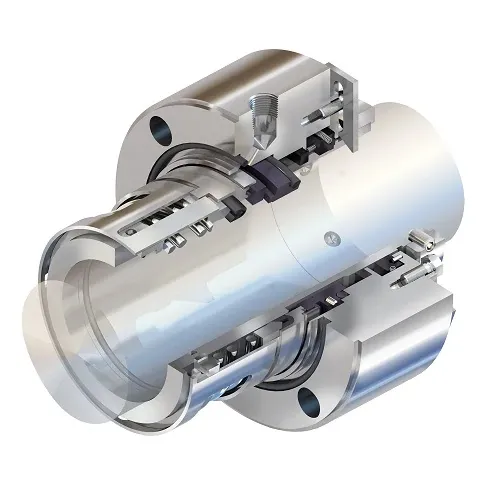

UC Series seals are balanced pusher seals with a substantial single coil spring that provides exceptional performance in the most demanding services including refineries, pipelines, and petrochemical services. UC seals are fully compliant with API 682, Type A requirements.

D Series seals are based on the UC Series, and add a pumping ring built into the rotating seal face body that establishes an exclusive Plan 23 cooling chamber around the seal faces. D Series seals excel in high temperature boiler feed water and hot hydrocarbon services.

- Extended service life in heavy-duty services assured by rugged single pusher seal with thick cross section components

- Increased reliability via large, low spring rate single coil spring that tolerates axial setting dimensions while reducing opportunity for clogging and hang-up from solids

- Consistent seal face contact provided by robust U-cup seal and spring holder

- Low-emissions performance enabled by silicon carbide rotating face mounted on graphite ring in UC and UCQ seals, preventing shrink fit distortions and sustaining a flat seal face

- High pressure performance in UO, UOP, D, and DP seals enabled by silicon carbide rotating face mounted on O-ring, preventing shrink fit distortions and sustaining a flat seal face

- Cost-effective operation ensured by integrated pumping ring in D and DP seals that establishes an exclusive Plan 23 cooling chamber around the seal faces and eliminates the expense of cool injection systems

API 682

Pressure:

- UC: up to 27.6 bar (400 psi)

- UO and D: up to 68.9 bar (1000 psi)

- UOP and DP: up to 103.4 bar (1500 psi)

Temperature:

- U Series: -40 to 204°C (-40 to 400°F)

- D Series: -73 to 343°C (-100 to 650°F)

Speed: up to: 23 m/s (75 fps)

Sizes: 14.1 to 148 mm (0.566 to 5.838 inch)

Arrangement 1 single seal (Common Piping Plans 11, 13, 32, 62)

UC

UCQ

UO

UOP

Arrangement 1 single seal (Common Piping Plan 23)

D

DP

Arrangement 2 unpressurized dual seal with dry running backup (Common Piping Plans 72, 75, 76)

UCQ/GSL

UOP/GSL