Product Brand

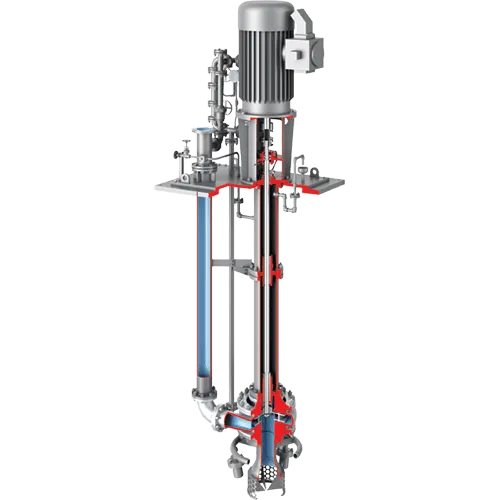

Lawrence Pumps® Type

Vertical Pumps SubType

Slurry Pumps- Numerous Impeller and Casing Designs allows the hydraulics to be tailored to the service requirements.

- Front and Rear Repelling Vanes replace erosion-prone wear rings.

- A Sparger System with it's agitation ring around the pump casing keeps coke particles in suspension to prevent silting-in of the pump. The ring is fed by either water from an outside source or through a filtration system.

- Sleeve Bearing Flush System prevents coke fines from entering the column pipe.

- Multiple Corrosion- and Abrasion-resistant Materials are available to suit application needs. Hard facing is avaialble on critical shaft areas.

API 610 VS4

- Flows to 1500 m3/h (6,600 gpm)

- Heads to 150 m (492 ft)

- Speeds to 1,800 rpm

- Temperatures to 100°C (212°F)

Size Range:

- NPS 3 to 8

Pressure Class Range:

- Class 150