Product Brand

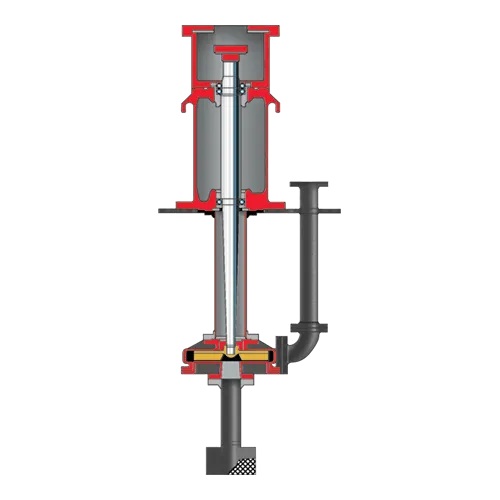

Lawrence Pumps® Type

Vertical Pumps SubType

Slurry Pumps- Custom Engineered Slurry Hydraulics ensure safe, reliable and efficient performance.

- High Chrome Iron Wet End resists abrasion. Heavy wall thickness on the wearing parts provides for longevity.

- The Impeller is keyed to the pump shaft and secured using an impeller nut. Clearances are easily adjustable at the thrust bearing location. Repelling vanes reduce wear and recirculation.

- Shafts are designed to operate approximately 30% below the first critical speed.

- Shaft Sealing is accomplished via packing with a nitrogen purge to prevent fugitive emissions.

- Heavy-duty, Anti-friction Thrust and Radial Bearings are located above liquid level and accommodate all axial and radial loads without transmitting any loads to the driver.

- Many Options are available to suit site requirements. These include:

- Inducer

- Suction tailpipe

- Basket-type screen

- Abrasion or corrosion-resistant materials of construction

- Several driver types

- ASME

- Flows to 4542 m3/h (20 000 gpm)

- Heads to 91 m (300 ft)

- Temperatures to 593°C (1100°F)

Size Range:

- NPS 1 to 12

Pressure Class Range:

- Class 150 to 600