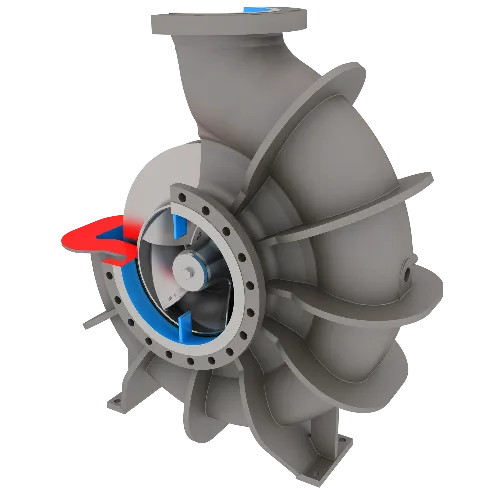

The Flowserve DS-RO single-stage, end-suction, foot-mounted pump is engineered specifically for auxiliary applications found in reverse osmosis desalination processes. This versatile pump is well-suited for plant support services such as filtered water, low- or high-pressure feed boosting, potable water, backwash and others. Optimized hydraulics and high-alloy materials of construction, like ASTM A890 Grade 5A/6A super duplex stainless steel, provide high-efficiency performance and long-term reliability that result in increased uptime with low cost of ownership.

... Read more Read less- A rigid shaft and double-volute casing keep shaft deflection low, reducing radial load and promoting high sustained efficiency.

- End-suction design with a choice of three alternative discharge nozzle locations provides system flexibility.

- Materials of construction are designed to withstand the corrosive environments typical of desalination processes.

- Double-volute casing provides stable operation. Radial thrust loads are minimized, reducing vibration and mechanical loads on all components.

- Parts interchangeability over a range of pump sizes lowers spare part inventories and costs.

- A spacer-type coupling allows full inspection of the back pullout type pump in minimum time, without disturbing suction and discharge connections.

- The closed impeller utilizes three dimensionally contoured blades extending into the impeller, combining high efficiencies and low NPSHR.

- Flows to 11,000 m3/h (48,432 gpm)

- Heads to 180 m (591 ft)

- Pressures to 27 bar (392 psi)

- Temperatures to 45°C (113°F)

- Frequency of 50 or 60 Hz; compatible with VFD applications

- Sizes from 200 to 700 mm (8 to 28 in)

For extended range, please consult with our specialists.

Sizes: DN 200 to 700 (8 to 28 in)

Pressure class: PN 27 bar (392 psi)

Materials:

- 316 stainless steel

- Super duplex (ASTM A890, Grade 5A; PREN ≥ 40)