Product Brand

Worthington® SubType

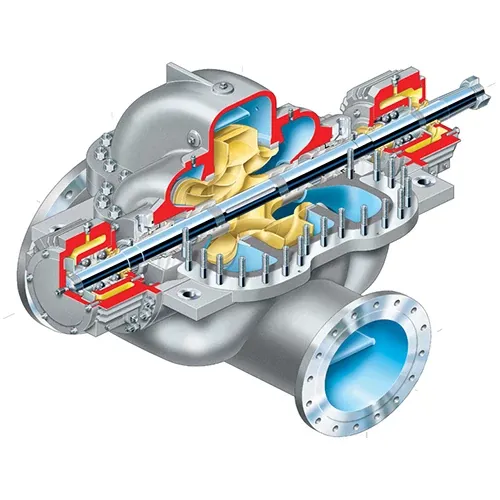

Single Case Pumps - Axially Split - API- High uptime made possible by double-suction impeller and double volute designs, which create optimal axial and radial thrust balance

- Increased MTBR resulting from heavy-duty bearings and bearing lubrication system; multiple options available to suit application requirements

- Superior performance at elevated temperatures with near-centerline mounting

- Simplified maintenance enabled by the split-casing design, which permits the rotor, seals and bearings to be serviced without disturbing the piping

- Emissions control with ISO 21049/API 682 seal chambers

- Centerline

- Nozzle loading capability beyond API 610, API 68

ISO 13709 / API 610 BB1

- Flows to 15000 m3/h (65000 gpm)

- Heads to 250 m (820 ft)

- Pressures to 50 bar (725 psi)

- Temperatures -80°C (-110°F) to 204° (400°F)

Size Range: 6" to 30"

Online Tools