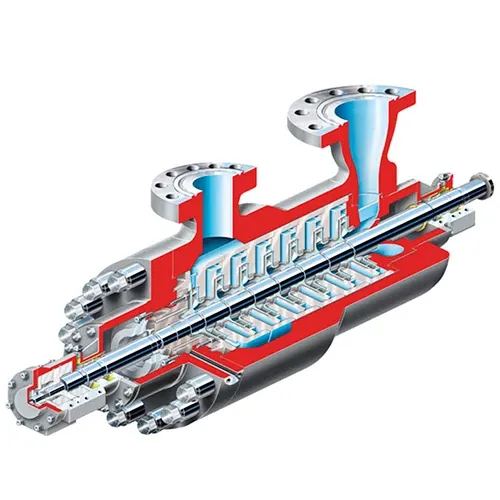

The WCC is a between bearing, multistage, double case, diffuser style barrel pump designed for medium duty applications in the oil & gas, chemical process industry and general industry markets. With numerous units installed, the Flowserve WCC(D) medium duty multistage barrel pump is a unique member of the double-case barrel pump family. The operating window is set out for the standard product range; however Flowserve has numerous installations in excess of this range what would be considered as fully engineered hydraulics and pump package.

... Read more Read lessThe rotor is built “in-line” or when required as an “opposed impeller” configuration. Precision cast Impellers of radial flow design. Individually dynamically balanced to G2.5 . Single suction first stage impellers on the smaller size and double suction is available on the bigger size types. Impellers are standard supplied with renewable wear rings on the front and back hubs, overlay material shall be selected to suit the application, DLD is the preferred method for applying hard coating of super duplex materials. Optional integral wear surfaces can be supplied. The standard rotor build is a stepped shaft design with shrink fit impellers individually keyed to the shaft. Impellers are secured against axial movement in in the direction of the axial thrust against the shaft shoulder. When required the impellers can be located to prevent axial movement in the reverse thrust direction by means of a split ring.

- ISO 13709 / API 610

- Hydraulic Institute

- Customer specifications

- Flows: 1000 m3/hr (4400 gpm)

- Head: 4000 m (13000 ft)

- Pressure: 300 bar (4350 PSI)

- Temperature: -73°C to 425°C (-100°F to 800°F)

- Flange ratings: 600# up to 2500#

- 6 sizes with discharges from 2" to 10" existing of 44 hydraulics

Size Range: 4 Sizes (3” to 8”) with 18 available hydraulics

WCCD (Double Suction)

WCCO (Opposed impeller configuration)

WCC-T (Hydraulic turbine)

WCC-TT (True turbine)