Visit Flowserve at WETEX 2023

Connect with us at booths 2-B27 and B28 (Hall No. 2) at WETEX, where our team of technology and service specialists are available to get a deeper understanding of your desalination plant needs. This provides an excellent chance to discuss the challenges you're facing and to explore Flowserve's energy-efficient solutions tailored to seamlessly integrate with your SWRO processes.

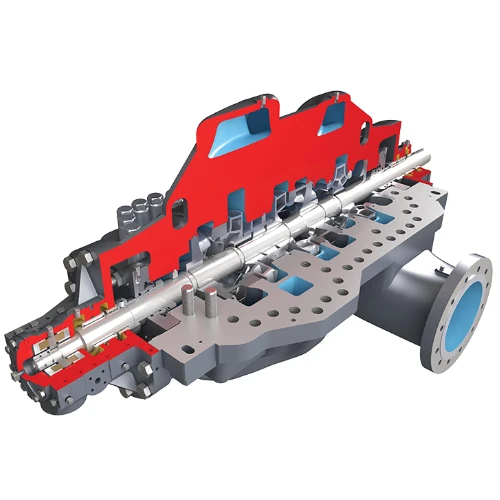

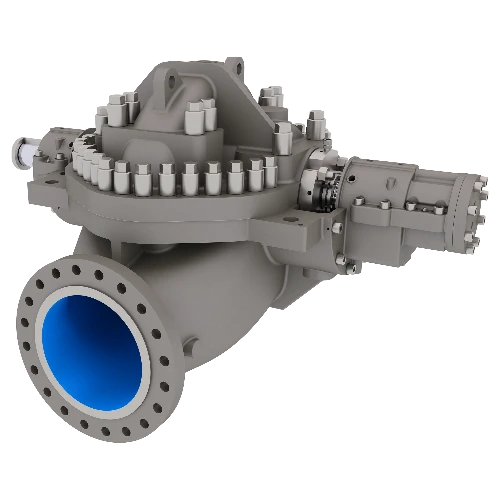

Flowserve’s holistic flow control approach focuses not just on pump efficiency but also pump and seal life by selecting the right metallurgy to support highly corrosive seawater pumping and brine applications. A prototype of our state-of-the-art energy recovery device, FLEX, will be demonstrated live giving you the opportunity to interface with our desalination product team.

Why Flowserve?

Offering a comprehensive, energy-efficient and scalable portfolio of integrated fluid motion and control systems, Flowserve enables desalination plants to operate economically and grow with demand. Our offerings include pumps for services such as seawater intake, membrane feed, ERD booster and auxiliary services as well as valves and ERDs.

Our pump and system specialists can answer your questions and address any process application issues you may have, from the simple to the complex. Here are some frequently asked questions, which we will be happy to address with you on-site:

- Do you have the capabilities to reduce energy consumption?

- What are your available digital solutions to increase plant MTBE?

- What support do you provide to manage inventories?

- How can a plant-user/operator depend on Flowserve to enhance workforce knowledge?

- How do you ensure compliance with safety and environmental operations?

- Why does FLEX score more than other energy recovery devices in any given desal-application?

- In case of another Covid-like global pandemic, does Flowserve ensure minimal supply chain disruptions?

Our Energy Advantage Program provides customers with Flowserve engineering expertise, a systematic data-driven evaluation process and a complete offering of products and services that can increase energy efficiency through optimization of pump and valve power consumption, reduce carbon emissions, improve plant productivity and reliability and provide operational savings.

Flowserve designed RedRaven as a comprehensive solution to monitor, analyze and predict the performance of your equipment — the collective lifeblood of your plant — so you can respond to problems quickly while minimizing disruptions and downtime. RedRaven is: Platform agnostic. Integrates with your existing plant control and is compatible with standard industry protocols.

About WETEX

The WETEX exhibition provides a leading platform for international organizations to present their latest solutions and products, and to learn about innovative technologies from all over the world in the sectors of energy, water, sustainability, green technologies, renewable and clean energy, sustainable development and water desalination technologies. Through specialized seminars and panel discussions, it also provides opportunities to exchange ideas with international experts and specialists.

The most aggressive fluids and slurries on the planet. High-volume and high-pressure applications that test the limits of hydraulic and mechanical designs. That’s where you’ll find Flowserve pumps and seals performing efficiently, safely and reliably. It’s a legacy that goes back centuries, one we build upon every day by outperforming expectations — no matter how great the demands.

RedRaven is Flowserve’s complete end-to-end internet of things (IoT) solution for the industrial space — a connected platform that gives you the tools and insights to monitor and optimize flow control equipment performance and proactively identify and address issues before they cause downtime and disruptions.

With RedRaven, you’ll have a turnkey offering that provides clear insights to improve your plant’s efficiency, productivity and reliability.

Worthington offers industrial process, between bearings, overhung slurry, vertical lineshaft, solids handling, cantilever, multistage, API 610, reciprocating, rotary gear and vertical turbine pumps.

Worthington pumps are designed for high efficiency, reliability, configuration versatility, long service life and low cost of ownership. They are used in a wide variety of water, power, oil and gas, mining, steel, and pulp and paper applications, including pipeline, circulating water, fire protection and irrigation. Worthington pumps are built to recognized global standards, as well as unique customer specifications.

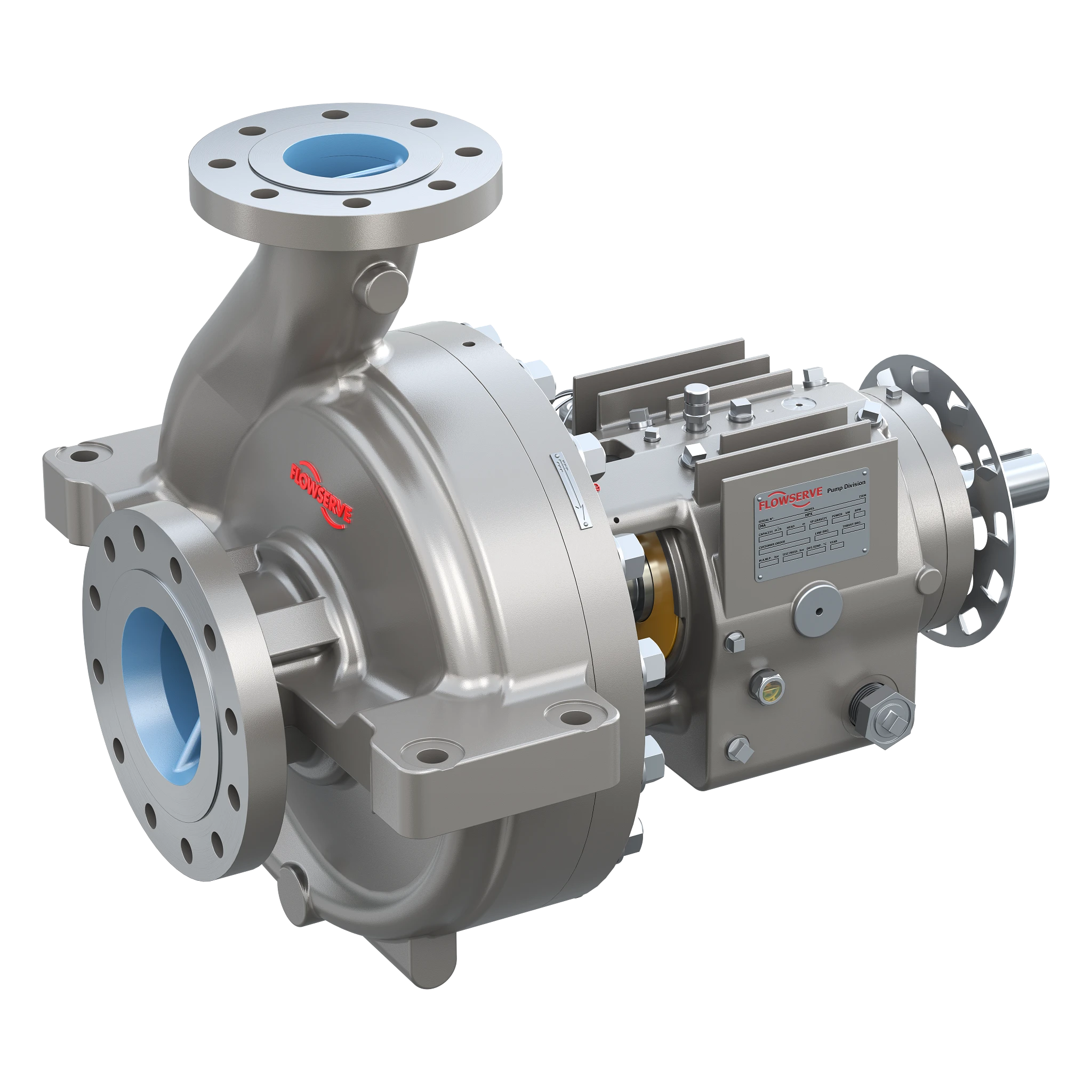

Durco was founded as the Duriron Casting Company in 1912. Its long history set the standard for ANSI chemical process pumps and robust plug valves. The brand is known for its durable designs, ease of maintenance, proven reliability, wide array of features and an extensive global support network. Complementary seals and seal systems are also available, enabling single-source convenience.

Highlights of Durco’s innovative history include the engineering and manufacturing of the world’s first Teflon® sleeve plug valve in the 1950s. The company has created unique materials, including Durimet-20 (Alloy 20) high alloy austenitic stainless steel — developed and patented in a joint effort with Ohio State University — and Durcomet 100 (CD4MCuN) duplex stainless steel in the 1960s. During the same decade, Durco introduced the first plug and butterfly valves fully lined with Teflon.

In 1997, Durco merged with BWIP, creating Flowserve Corporation.