Predictive maintenance and digitization

Flowserve recognizes the need to accelerate energy transition initiatives quickly and cost-effectively. Our unrivaled combination of technical expertise and practical application can help energy sectors transition to cleaner, renewable energy sources and more sustainable industrial processes.

Flowserve’s oil and gas experts, product managers and sales specialists will be on hand at booth #12 to showcase our digital portfolio highlighting RedRaven, the predictive maintenance capabilities of our flow control solutions. We are committed to IoT development and integrating our devices to stay at the forefront of industry innovation.

Visitors to the Flowserve booth will have the opportunity to see the extended capabilities of the FlowSync app, which enables with Bluetooth connectivity of our Limitorque MXb actuators. By prioritizing digitization and embracing cutting-edge technology, Flowserve is able to offer reliable, efficient solutions that meet your needs.

Why Flowserve?

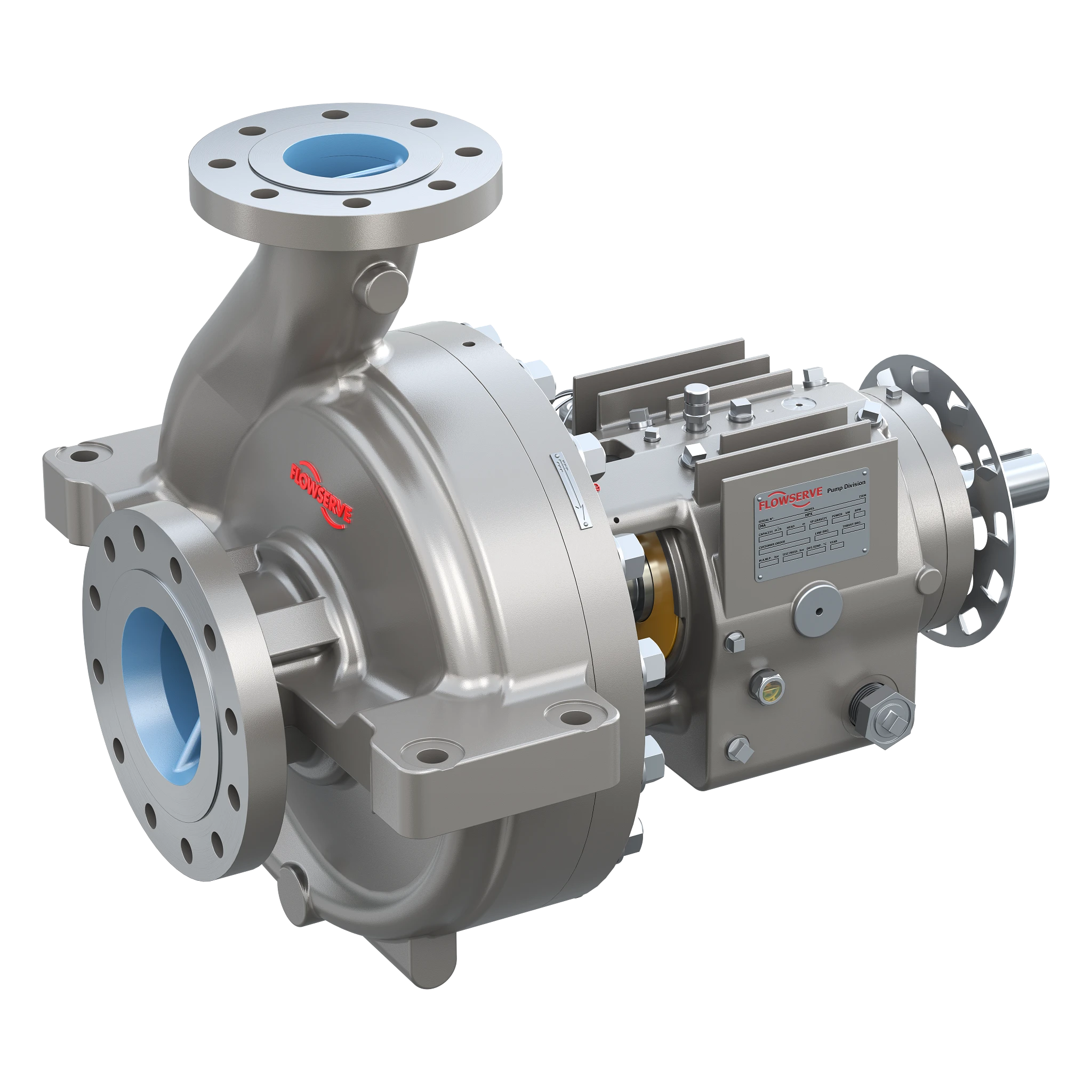

From deep ocean floors to remote well fields and oil sands. From up stream production to transportation to refining. No matter how remote the locations, Flowserve has the pump, valve and seal solutions you need to construct and maintain your operations. The world’s leading oil and gas companies rely on Flowserve for the industry’s most complete flow management portfolio.

Flowserve’s environmentally responsible solutions are helping customers meet their own sustainability goals, including reducing carbon emissions. Our broad product offering — coupled with real-time system analysis, predictive maintenance and remote services capabilities — equips customers with end-to-end intelligence that maximizes uptime, throughput and reliability.

Visit Flowserve

Achieve your operational, sustainability and energy transition objectives with Flowserve. Visit us at Endress+Hauser Global Forum, where our specialists will be eager to address questions on how our products and solutions can support your energy transition, sustainability and operational initiatives.

About Endress+Hauser Global Forum

The Endress+Hauser Global Forum is inviting customers, partners and industry experts to jointly discuss the sustainable transformation of the process industry.

The most aggressive fluids and slurries on the planet. High-volume and high-pressure applications that test the limits of hydraulic and mechanical designs. That’s where you’ll find Flowserve pumps and seals performing efficiently, safely and reliably. It’s a legacy that goes back centuries, one we build upon every day by outperforming expectations — no matter how great the demands.

From its beginnings in 1966, Kämmer has manufactured special application and general service control valves and actuators. Kämmer solutions are used extensively in the chemical, petrochemical, power, petroleum, pulp and paper, pharmaceutical, food processing and cryogenic industries.

Although more than half of all Kämmer valves are custom-designed, custom applications often don’t require additional time or cost because of the versatility and interchangeability of the Kämmer valve design.

Since 1929, Limitorque actuators have been making flow control easier among a broad range of applications. These actuators are world-class devices used to consistently drive multi-turn and quarter-turn industrial valves and dampers, providing years of dependable service. More than 1 million Limitorque actuators have been installed around the world — and some have been in operation for more than a half-century.

Limitorque changed the industry with its strategic introduction of a “torque-limiting” design. Today, all heavy-duty electric actuators use some device that “limits the torque” to safely operate automated valves and protect people and property.

RedRaven is Flowserve’s complete end-to-end internet of things (IoT) solution for the industrial space — a connected platform that gives you the tools and insights to monitor and optimize flow control equipment performance and proactively identify and address issues before they cause downtime and disruptions.

With RedRaven, you’ll have a turnkey offering that provides clear insights to improve your plant’s efficiency, productivity and reliability.