Visit Flowserve at TPS 2023

You’re invited to join us at Turbomachinery and Pump Symposia (TPS) in Booth 2235, Hall D to discover the complete portfolio of Flowserve solutions and to talk with our fluid motion and control specialists. They’re your source for expert knowledge essential to optimizing seals, pump systems, and valves. Flowserve has the specialized expertise to advise you on best practices to improve your asset management strategies, enhance your operational procedures, and address today’s global flow control management challenges.

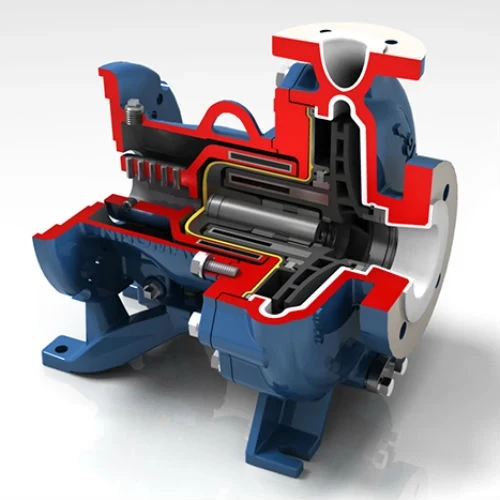

We will demonstrate our capabilities across seals and support systems, pumps and valves. You will have first-hand interaction with equipment to enable you to experience the functionality, reliability and quality – directly. Our team of product specialists will be available to answer questions and discuss your requirements in detail.

Why Flowserve?

Regardless of application, Flowserve can provide the solution. Whether your main concern is weathering corrosive and other exceptionally tough conditions, or ensuring consistent and precise output, Flowserve has solutions to handle the demands of your industry. We’re a one-stop shop. We can equip your plant with products and deliver service offerings ranging from front-end project engineering support to reliable and responsive maintenance and repair that minimizes unexpected downtime. All the while, we’re helping to maintain the safety of your people and the integrity of the surrounding environment.

We also offer RedRaven IoT digital solutions for condition monitoring and predictive analytics that enable plants to proactively maintain equipment and avoid unplanned downtime. Flowserve is evolving flow control autonomously using our digital offerings to make improvements in the efficiency, productivity, safety and sustainability.

Flowserve recognizes the need to accelerate energy transition initiatives quickly and cost-effectively. Our unrivaled combination of technical expertise and practical application can help energy sectors transition to cleaner, renewable energy sources and more sustainable industrial processes.

The Energy Advantage Program provides customers with Flowserve engineering expertise, a systematic data-driven evaluation process and a complete offering of products and services that can increase energy efficiency through optimization of pump and valve power consumption, reduce carbon emissions, improve plant productivity and reliability and provide operational savings.

About TPS

Rotating equipment and pump engineers and technicians worldwide, spanning oil and gas, petrochemical, power, aerospace, chemical and water industries will gather at TPS. Nearly 5,000 people and representatives of 365 exhibiting companies are expected to attend to exchange ideas and learn more about maintenance, reliability, troubleshooting, emerging designs, technology, and best practices.

The most aggressive fluids and slurries on the planet. High-volume and high-pressure applications that test the limits of hydraulic and mechanical designs. That’s where you’ll find Flowserve pumps and seals performing efficiently, safely and reliably. It’s a legacy that goes back centuries, one we build upon every day by outperforming expectations — no matter how great the demands.

SIHI is the leading manufacturer of liquid pumps, vacuum pumps and engineered systems used in all segments of the process industry. They are found in applications as diverse as basic and fine chemicals, pharmaceuticals, food and beverage processing, machinery manufacturing, general industry applications, energy generation, municipal water and heavy machinery applications.

SIHI was founded in Germany in 1920 as Siemen & Hinsch (SiHi) by Otto Siemen and Johannes Hinsch, inventors of the self-priming side channel pump for liquids and gases. This was the beginning of a history of innovation, which later included the development of multistage centrifugal pumps, liquid ring vacuum pumps, so-called “combi-pumps” (centrifugal pumps with self-priming stages), volute casing pumps, magnetic drive systems and dry-running vacuum pumps.

The brand was acquired by Flowserve in 2015. SIHI’s liquid and vacuum pumps, compressors and systems continue to enhance and strengthen Flowserve’s position as the world’s leading supplier of chemical process pumps and systems.

Shaft seals and ball bearings are the weakest link in any pumping system, accounting for nearly 80% of all process pump failures. INNOMAG pumps address this critical weakness by eliminating both.

But that’s just the beginning.

INNOMAG pumps are also the first to address the inherent weakness of sealless pumps — process lubrication — which accounts for nearly all sealless pump failures. The revolutionary thrust-balanced design of INNOMAG pumps addresses the problem by reducing its dependency on process lubrication by more than 90% compared to traditional thrust-forward designs.

In addition, INNOMAG pumps are hermetically sealed. That means no leaks when they work and, in most cases, no leaks — even if they fail. As a result, they’re not only cleaner and safer for operators and the environment but also more cost-effective, consuming 10 to 46% less energy on average than typical sealed and sealless pumps.

This unique and patented technology not only takes sealless pump reliability to a whole new level, but also makes INNOMAG the first and only sealless pump capable of handling significant solids — up to 30% concentration by volume and up to ¼ in particle size.

INNOMAG pumps come in only one material option with near-universal chemical resistance, enabling a single pump model to cover a wider range of duty points and services. This allows you to standardize your pump fleet and optimize your spare parts inventory.

The versatility and simplicity of INNOMAG pumps make it possible to ship from stock in 5 days or less with better than 98% on-time delivery.

RedRaven is Flowserve’s complete end-to-end internet of things (IoT) solution for the industrial space — a connected platform that gives you the tools and insights to monitor and optimize flow control equipment performance and proactively identify and address issues before they cause downtime and disruptions.

With RedRaven, you’ll have a turnkey offering that provides clear insights to improve your plant’s efficiency, productivity and reliability.