Visit Flowserve at WNE 2023

You’re invited to meet with our nuclear industry specialists at the World Nuclear Exhibition (WNE) in Booth J014 to discover more about Flowserve’s unrivaled combination of technical expertise, practical application knowledge, and broad range of fluid motion and control products.

Nuclear plant operators ensure uptime by utilizing our global network of Quick Response Centers and enhance your nuclear plant’s reliability and safety. Our team can help you improve the performance and efficiency of fluid control equipment utilized in power plant operations. As your partner, Flowserve enables you to choose the best possible flow control solutions for your most challenging nuclear applications.

You’ll benefit from the expertise our specialists have built during seven decades of serving the nuclear power industry. Flowserve has been a pioneer of many significant advancements in pumping technology to meet the requirements of nuclear steam supply system (NSSS) and balance of plant (BOP) or steam-side fluid movement and control applications.

Why Flowserve?

As a leader in flow control solutions, Flowserve has developed flow control products using an unrivaled combination of technical expertise and practical application knowledge. This approach has resulted in reliable products proven to increase plant uptime, enhance operational efficiency and reduce costs.

As a single point of contact, lean on us for:

- Commissioning and operations with plant managers and technicians.

- Nuclear product offerings for new builds (Gen III, III+ and GenIV) and existing reactors.

- Project planning with engineering, procurement and construction (EPC) consultants and company project managers.

- Unparalleled service and technical support expertise backed by a global network of Quick Response Centers.

From the first nuclear plants in the 1950's to today's advanced reactor designs, Flowserve has provided products satisfying the highest-quality standards in the nuclear industry, 5,000+ pumps and 15,000+ valves have been installed in over 200 global reactors. We understand the stringent demands for safety, performance and nuclear services in support maintenance, repair and operations (MRO).

Benefit from our nuclear power certifications and compliance record:

- Flowserve is certified in / knowledgeable of ASME Section III, RCC-M, JSME and HAF 604

- Flowserve maintains nuclear stamps N, NR, NPT stamps, ASME Section VIII 'U' stamp.

- Flowserve provides Class 1, 2 and 3 safety-related equipment for pumps, valves and seals, parts, repairs and services.

- Flowserve adheres to nuclear and industry quality management standards such as ISO 9001, GS-R-3, NQA-1 and NSG-100.

- Flowserve is in complete compliance with nuclear regulations 10CFR50 App B, 10CFR21, ANSI N-45, ASME IX, NBIC-NR, CAN3 Z-299 and CSA N285.0.

About WNE

WNE brings together more than 600 exhibiting companies, 40% of which are international, working in nearly 50 activities covering the entire value chain of the industry. This unique offer makes it the reference event for the civil nuclear industry. WNE presents the leading French and international companies in the sector, as well as many young innovative companies.

The most aggressive fluids and slurries on the planet. High-volume and high-pressure applications that test the limits of hydraulic and mechanical designs. That’s where you’ll find Flowserve pumps and seals performing efficiently, safely and reliably. It’s a legacy that goes back centuries, one we build upon every day by outperforming expectations — no matter how great the demands.

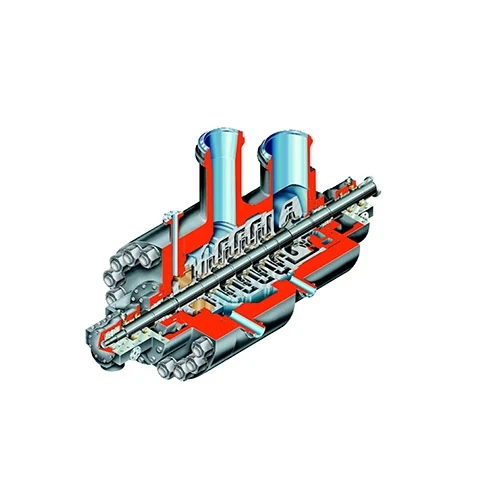

Founded in 1872, Byron Jackson offers oil-filled submersible, nuclear, volute casing, between bearing, overhung and vertical pumps and a liquid cryogenic turbine-generator expander.

Byron Jackson has been the sole source pump supplier for ebullated bed residue hydrocracking since 1967, with more than 80 installed pumps worldwide.

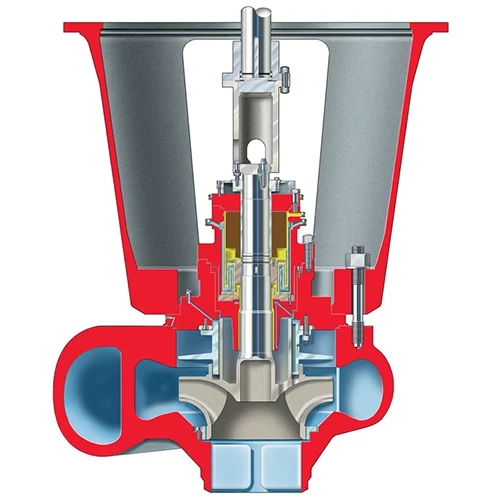

With its SUBM suite of pumps, Flowserve offers one of the broadest range of deep-well submersible pumps in the world. Along with extensive hydraulic coverage, SUBM pumps offer oil-filled or water-filled submersible motors, enabling you to specify the pumping system that best meets your application, specification and lifecycle cost requirements.

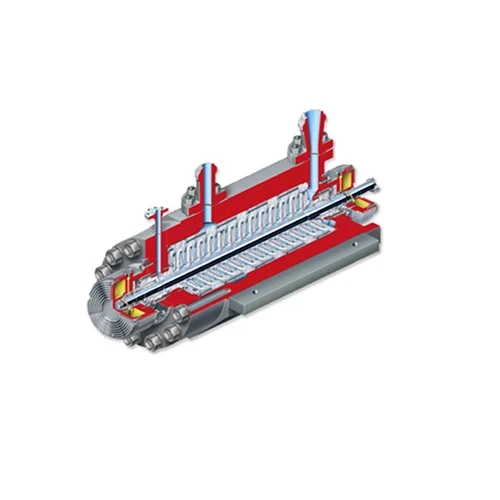

Founded in 1871 and acquired by Flowserve in 2000, IDP manufactures centrifugal, diaphragm, reciprocating, rotary and turbine pumps. Products range from utility and high-energy pumps, API-610, and ISO and ANSI chemical process pumps to magnetic drive and vertical turbine, sewage and nonmetallic units.

Notable accomplishments for IDP include main feed pumps for the first nuclear-powered submarine, the world’s largest boiler feed pumps and pipeline pumps driven by gas turbine engines. Specialty applications include nuclear pumps for chemical and volume control, a vertical multistage process pump for cryogenic applications, plus the most rugged and dependable vertical turbine snowmaking pumps for ski resorts and athletic venues.

Worthington offers industrial process, between bearings, overhung slurry, vertical lineshaft, solids handling, cantilever, multistage, API 610, reciprocating, rotary gear and vertical turbine pumps.

Worthington pumps are designed for high efficiency, reliability, configuration versatility, long service life and low cost of ownership. They are used in a wide variety of water, power, oil and gas, mining, steel, and pulp and paper applications, including pipeline, circulating water, fire protection and irrigation. Worthington pumps are built to recognized global standards, as well as unique customer specifications.