Visit Flowserve

The 2023 Motor-Operated Valve Users Group (MUG) Conference, January 23-27, 2023, in Clearwater Beach, Florida, brings together nuclear power plant operators and industry leaders to share information that can enhance the reliability and safety of their facilities.

Meet with Flowserve’s technology and product experts at the 2023 MUG Conference to learn more about our unrivaled combination of technical expertise, practical application knowledge, and fluid motion and control products. We look forward discussing your critical needs for reliable valve and actuator solutions.

You’ll also learn more about the Limitorque® SMB multi-turn actuator from Flowserve, which delivers long service life owing to its rugged cast iron housing and precision-machined gearing.

You can reduce maintenance and avoid downtime thanks to its torque-limiting feature, which de-energizes the motor to prevent valve damage in the event of an obstruction. The Limitorque SMB valve is ideal for applications with torque ranging from 15 ft-lb (20 Nm) to 60,000 ft-lb (81,349 Nm) and stem thrusts up to 500,000 lbs. (2,224 kN). As a result, the Limitorque SMB valve makes control easier whenever the application demands maximum durability.

Why Flowserve?

Flowserve engineers and specialist understand the supercritical conditions in a nuclear power plant. That’s why 80% of world’s main steam and main feedwater Isolation valves installed since 1985) are supplied by Flowserve.

We help customers to reduce unplanned downtime while protecting personnel and property. Nuclear plant operators ensure uptime by utilizing our global network of Quick Response Centers and enhance your nuclear plant’s reliability and safety.

Our team can help you improve the performance and efficiency of fluid control equipment utilized in power plant operations. As your partner, Flowserve enables you to choose the best possible flow control solutions for your most challenging applications. When your processes required actuation equipment that offers unsurpassed strength and durability, you’ll benefit from the expertise our specialists have built during five decades of serving the nuclear power industry.

About MUG 2023

MUG is a forum for nuclear utility representatives who exchange technical information relating to the testing and maintenance of motor-operated valves. They also coordinate among the utilities and other organizations within the nuclear industry to increase the reliability and safety of nuclear power.

Edward high-performance isolation valves are designed for critical service applications with temperatures exceeding 1,000°F and pressures surpassing 10,000 psi. The product line includes a variety of gate, globe, check, blowdown, bolted bonnet, nuclear and univalves from Edward, Equiwedge® and FliteFlow.

First manufactured in 1904, Edward valves have reliably met or exceeded customer expectations for more than a century, becoming the preferred choice for power plants, process facilities and other critical services.

Anchor/Darling specializes in critical service valves for the power industry. The brand’s heritage dates to 1888 (for Darling) and 1950 (for Anchor). Anchor/Darling valves are designed to meet stringent nuclear standards, delivering proven reliability, safety, quality and long service life.

Argus was founded in 1948. The brand produces high-quality engineered ball valves for the harshest conditions, including severe service applications prone to abrasion, corrosion and erosion. Specifically, Argus valves are commonly found in critical liquid and gaseous services in chemical, petrochemical and refinery operations. They fulfill the highest demands of fugitive emissions (FE) under ISO 15848. Special and customized designs are available for high-pressure, high-temperature and challenging applications like oxygen, nitrogen and hydrogen.

Argus specializes in metal-to-metal gas tightness applications with HVOF and spray and fuse coating (Arguloy), which enables a wide range of custom solutions. The brand introduced an innovative coating technology in 2009, followed by a new laser coating and cladding technology in 2014.

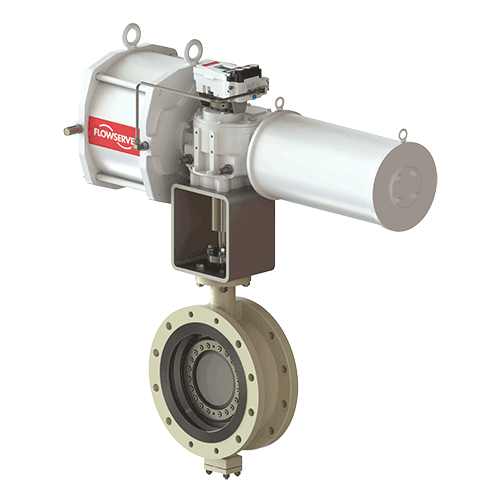

Founded in 1965, Valtek revolutionized traditional control valves by adding a high-pressure piston actuator to enable maximum stiffness, plus a simple, one-touch calibration positioner. The result is a superior level of process control and simple, intuitive operation, resulting in more efficient and profitable operations.

Reliability, long life, parts interchangeability, ease of maintenance and prompt delivery are hallmarks of the Valtek brand.

| Name | Speaker | Date |

|---|---|---|

| Thu, 06/22/2023 |

| Name | |

| Speaker | |

| Date | Thu, 06/22/2023 |

| Name | Speaker | Date |

|---|---|---|

| Thu, 06/22/2023 |

| Name | |

| Speaker | |

| Date | Thu, 06/22/2023 |