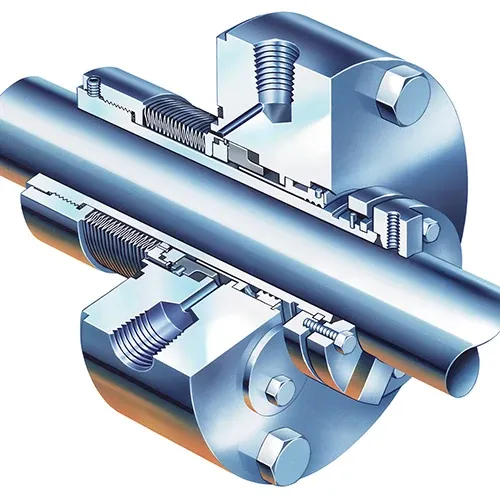

BRC Series edge-welded metal bellows seals are exceptionally robust and designed to seal high-temperature hydrocarbons, heat transfer fluids and severe services in refineries and hydrocarbon processing plants. The BRC series is fully compliant with API 682 Type C requirements and features thick-plate Alloy 718 bellows convolutions for superior corrosion resistance.

... Read more Read less- Longer service life ensure by the use of edge-welded, thick-plate Alloy 718 bellows that comply with NACE MR0103 criteria and can withstand long-term chemical exposure

- Reliability resulting from the canned face design that eliminates shrink-fit distortions and allows low-leakage performance

- Prolonged clean operation (on stationary configurations) due to steam purge baffle that eliminates coking

- Configurable with a rotating or stationary bellows to fit a wide range of high temperature application needs

API 682

Pressure: up to 20.7 bar (300 psi)

Temperature: -73°C to 427°C (-100°F to 800°F)

Speed: up to 23 m/s (75 fps)

Sizes: 28.2 to 150 mm (1.110 to 5.906 inches)

BRCH

Utilizes a bolted bellows adapter for convenient repairs when necessary

BRCS

Shorter version designed to fit pumping equipment with axial length restrictions and when dual seals are required

Arrangement 1 single seal (Common Piping Plans 11, 13, 23, 32, 62)

BRC

BRCH

Arrangement 2 unpressurized dual wet seal (Common Piping Plans 52)

BRCSH/BRCSH

Arrangement 2 unpressurized dual seal with dry running backup (Common Piping Plans 72, 75, 76)

BRCSH/GSDH

Arrangement 3 pressurized dual wet seal (Common Piping Plans 53A, 53B, 53C, 54)

BRCSRW/BRCSRW