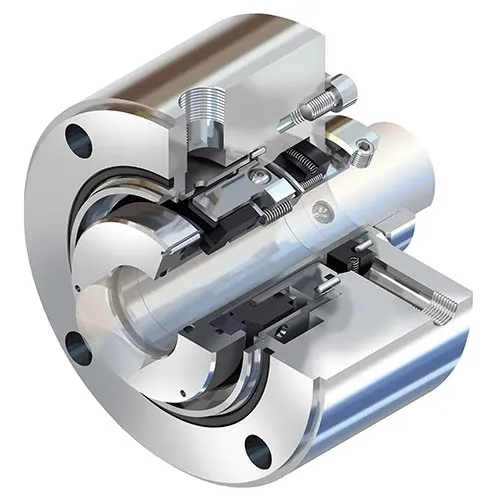

HSH seals are built for extended reliability in high pressure, high speed and highly viscous services such as mainline crude oil pipeline pumps. HSH seals are balanced, flexible stator cartridge seals with drive mechanisms and seal face geometries engineered for high torque loads and long-term performance. The HSH seal is fully compliant with API 682 Type A requirements.

... Read more Read less- Extended service life via high torque-capable anti-rotation lugs that minimize distortion and wear

- Greater efficiency from standard distribution ring connected to the seal’s flush port, which improves cooling efficiency by injecting flush flow 360° around seal faces

- Reliable high speed operation and improved tolerance of misalignment enabled by flexible stator design with Alloy C-276 spring

- Decreased inventory costs and increased design flexibility owing to parts interchangeability between single and dual seal arrangements

API 682

- Pressure: up to 103 bar (1500 psi)

- Temperature: -40 to 260°C (-40 to 500°F)

- Speed: up to: 46 m/s (150 fps)

- Sizes: 25.4 to 156 mm (1.000 to 6.125 inch)

Arrangement 1 single seal (Common Piping Plans 11, 13, 23, 32, 62)

HSH

Arrangement 2 unpressurized dual wet seal (Common Piping Plans 52)

HSH/HSH

Arrangement 2 unpressurized dual seal with dry running backup (Common Piping Plans 72, 75, 76)

HSH/GSL

Arrangement 3 pressurized dual wet seal (Common Piping Plans 53A, 53B, 53C, 54)

HSH/HSH