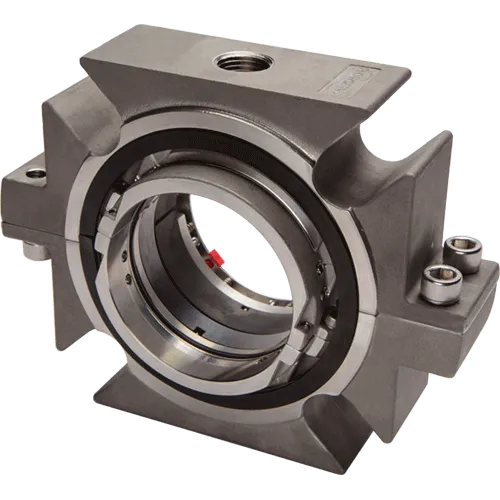

Advanced technology semi-cartridge split seal for pump and mixer applications. The PSS 4 split seal, with intrinsic joint alignment technology, provides the easiest and most successful installation to make reduced equipment downtime and increased reliability routine.

... Read more Read less- Exclusive 3D Key technology assures optimum face alignment in both axial and radial direction, reducing leakage and installation time.

- Unique setting tabs optimally position the rotating face for installation while eliminating all seal positioning, measuring and marking, further assuring first time/every time installation success.

- Easily handles mixer equipment runout up to1.5 mm (0.060 inch) TIR radial shaft movement, accommodating demanding mixer characteristics.

- Fully split designs installs easily around the shaft, outside of the seal chamber, eliminating the need to dismantle the equipment for seal installation.

- Easy installation made even easier with fully pre-assembled, unitized component, semi-cartridge design.

Full vacuum to 30 bar (450 psi), -18° to 121°C (250°F), up to 19.3 m/s (3800 fpm), 38 to 152 mm (1.500 to 6.000 inch)

Size Range: 1.500" to 6.000