Product Brand

Flowserve Type

Mechanical Seals SubType

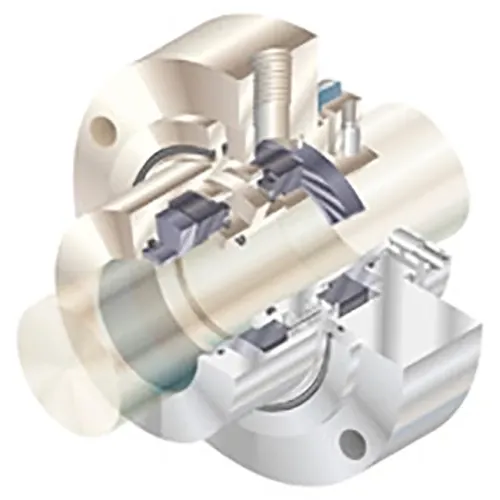

Gas Barrier and Containment Seals- Dual seal pressurized with an inert gas barrier operates with zero process emissions to satisfy environmental monitoring requirements

- Silicon carbide seal faces use APGS Precision Face Topography to separate the faces with a stiff, thin gas film that prevents wear and extends seal life

- The LoDragTM O-ring technology provides consistent dynamic O-ring squeeze to reduce drag and maintain proper seal face tracking

- Seal faces are optimized by geometry, materials, spring loads, and drive mechanisms to remain flat under all operating conditions and deliver long-term, reliable performance

- Non-contacting seal faces require very low power consumption during start-up and running operation

Up to 35.4 bar (500 psi), -40 to 260°C (-40°F 500°F), up to 25 m/s (83.3 fps), 25.4 to 152 mm (1.000 to 6.000 inch)

Online Tools