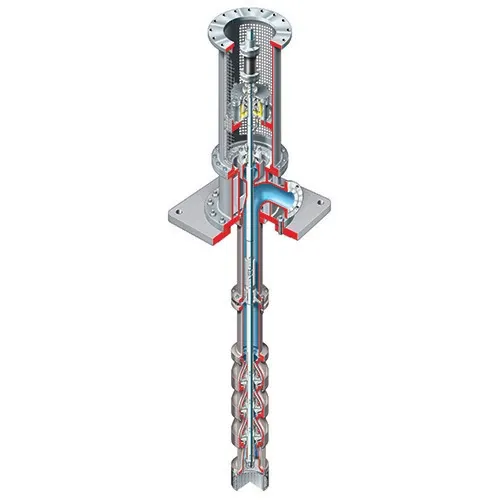

The Flowserve WUJ is a multistage, heavy duty single casing vertical turbine pump in compliance with ISO 13709/API 610 (VS1) requirements. The WUJ is designed for continuous, un-spared duty in a variety of severe services, including high pressure and temperature extremes at wet pit or deep well applications.

... Read more Read less- The Flowserve WUJ is a multistage, heavy-duty single casing vertical turbine pump designed to current international standard API 610 / ISO 13709, VS1 designation

- WUJ pumps are available with either radial or mixed flow hydraulics to suit application requirements

- They are designed for continuous, un-spared duty in a variety of severe services, including high pressures and temperature extremes

- WUJ pumps have maximum design and operating flexibility, they can be equipped with inducers or double suction first impeller for selected hydraulics, installation length up to 40 m (131 ft), axial thrust tilting pad bearing for ultra high thrust operations, rigid spacer coupling to ease seal assembly, centralizer and guide rings for deep well installations, hypochloride piping to prevent marine growth at seawater applications, anodic protection to prevent corrosion, steam injection or electrical heating to prevent icing in cold climate and many engineered installation solution to fit the pump for customer needs

- WUJ pumps can be provided in compliance with ATEX Zone 0 / Category 1

Flowserve

Hydraulic Institute

ISO 13709 / API 610

ISO 21049 / API 682 seal chamber and seal flush plans

ASME VIII, Div 1 and ASME IX

ATEX, PED, AD2000

- Flows to 500 m³/h (2200 gpm) for radial hydraulics; to 3000 m³/h (13200 gpm) for mixed flow hydraulics

- Heads to 2000 m (6500 ft) for radial hydraulics; to 600 m (1950 ft) for mixed flow hydraulics

- Temperatures from -200°C (-325°F) up to 350°C (660°F)

- Pressures to 200 bar (2900 psi) for specific radial hydraulics; to 64 bar (930 psi) for specific mixed flow hydraulics

Size Range:

- 55 hydraulics (radial hydraulics / mixed flow hydraulics)

- Up to 20 stages

- Installation length up to 40 m (131 ft)