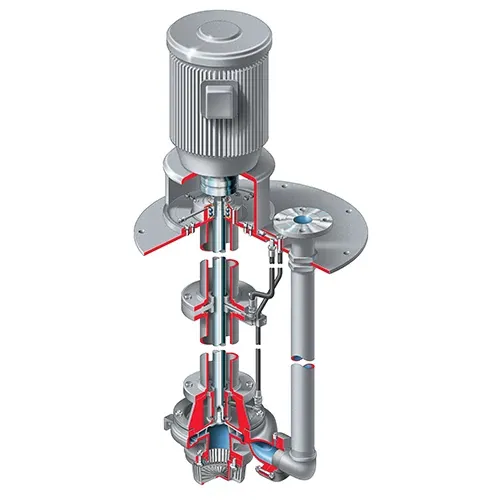

Boasting the same casing, reverse vane impeller and CBL cover as the industry-leading Durco Mark 3 chemical process pump, the ESP3 pump is ruggedly built to handle tough applications. It is the only vertical wet-pit immersion sump pump to offer parts interchangeability with standard ASME B73.1 horizontal pumps. The upshot is increased parts standardization and reduced inventory costs.

... Read more Read lessThe ruggedly built vertical, chemical sump pump is designed to provide improved performance, increased part standardization and reduced inventory costs.

- Increased parts standardization and reduced inventory costs from the only vertical wet-pit immersion sump pump to offer parts interchangeability with standard ASME B73.1 horizontal pumps (Durco Mark 3)

- Repeatable performance for the life of the pump due to reverse vane impeller

- Reduced maintenance and downtime in difficult process fluids owing to a wide array of wetted materials, bearing materials and flush plan options

- Low total cost of ownership made possible by many features designed to reduce costs associated with installation and maintenance

- Flows to 1300 m3/h (5700 gpm)

- Heads to 116 m (380 ft)

- Pressures to 12 bar (175 psi)

- Temperatures to 180°C (350°F)

Size Range:

- Sizes from 25 mm (1 in) to 200 mm (8 in)

- Pit depths to 6 m (20 ft); greater depths achievable with optional tailpipe