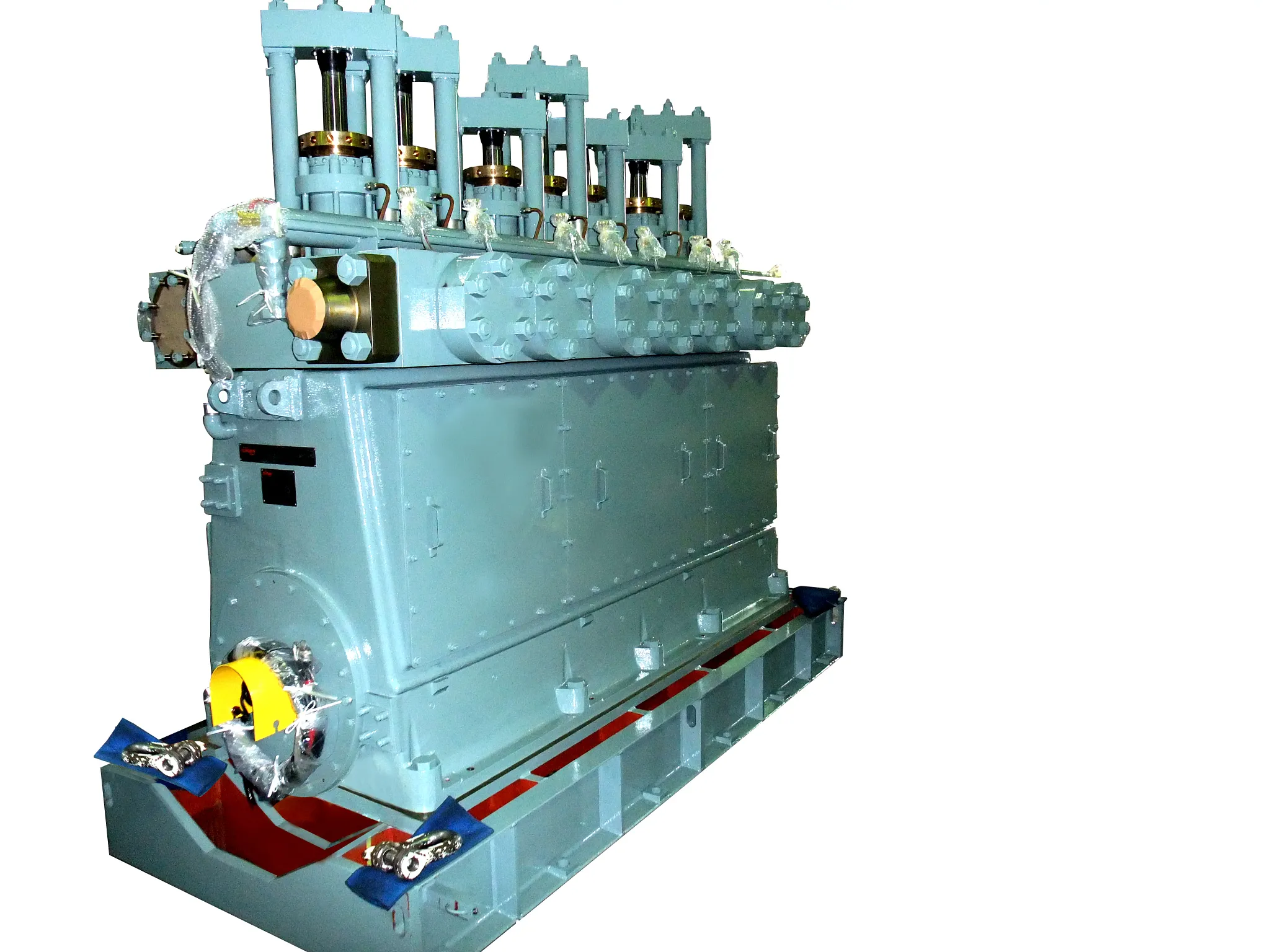

- Monoblock liquid ends for both oil & gas and general industrial services

- Self-aligning plungers ensure proper concentricity within stuffing boxes

- Many valve styles to suit all liquid types

- Stuffing boxes outboard of cylinder allowing for more complex sealing and piping arrangements

- Stuffing boxes individually fastened to liquid cylinder for ease of maintenance

- Totally enclosed power frame is dust and oil tight eliminating atmospheric contamination

- Cylindrical crossheads and guides maximize the load bearing area and reduce wear, keeping replacement costs to a minimum

- Full pressure lubrication systems to ensure all bearing areas are protected and run smoothly

Flowserve

- Flows to 410 m³/h (1800 gpm)

- Pressures to 431 bar (6250 psi)

- Temperatures from -40°C (-40°F) to 360°C (680°F)

Size Range: 178 mm (7.00") stroke, with 31.75 mm (1.25") to 146.05 mm (5.75") diameter plungers, with power rating of 1446 kW.

Standard Design

Monoblock liquid end with clean liquid valves and full pressure bearing lubrication

High Suction Pressure Design

Special crosshead pin bearings and lubrication system to cope with non-unloading of that bearing

High Liquid Temperature Design

Individual cylinders and special manifold fastening arrangement to cope with thermal expansion effects on plunger centre distance

Slurry Design

Special liquid end arrangement for constant velocity flow, stuffing box flushing, and slurry valves to cope with solids in the liquid