Product Brand

Worthington® Type

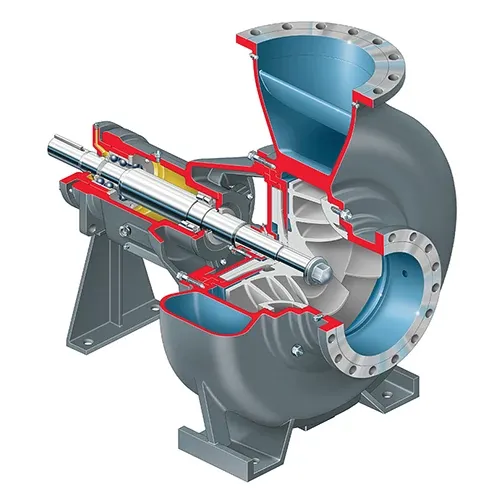

Overhung Pumps SubType

Industrial Process Pumps- Self-Venting, Top Centerline Discharge Casing with unobstructed suction prevents trapped air to maintain efficiency and flow Keyed Semi-Open, Full Vane Impeller prevents clogging in thick, pulpy applications and is less sensitive to end clearance adjustment

- Recessed impeller available for low-shear applications

- Three-Point End-Clearance Adjustment resets impeller clearance to restore performance and efficiency

- Extra Heavy-Duty, Alloy Steel Shaft minimizes problems associated with overhang, deflection and vibration

- Stainless steel available.Contoured Wearplate at the impeller suction side protects casing and prolongs pump efficiency

- “Dry-shaft” Construction, using sealed impeller nut and key driven stainless steel hook sleeve, eliminates shaft corrosion

- Optional Large Conical Seal Housing allows the seal to be installed in the liquid directly behind the impeller, eliminating the need for a separate seal water flushing source

- Optional Flow Inducer significantly improves suction performance by reducing pump NPSHR

- Optional Expeller forces fluid from the seal chamber, minimizing shaft wear

- Positioned behind the impeller, the expeller eliminates the need for costly flush water and the resulting product dilution

Flowserve Hydraulic Institute

- Flows to 9085 m3/h (40 000 gpm)

- Heads to 100 m (325 ft)

- Pressures to 14 bar (200 psi)

- Temperatures to 150°C (300°F)

Size Range: Sizes from 50 mm (2 in) to 200 mm (8 in)

FRBHS

Recessed Impeller

FRBHX

Expeller Option

FRBHC

Dry pit vertical close coupled

Online Tools