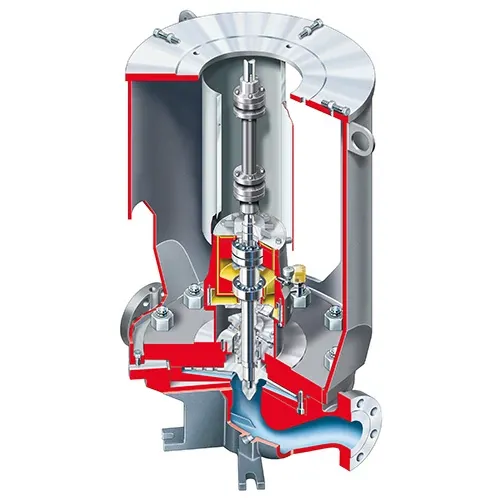

The HWMA is a single or two stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint, this low-flow, high-head process pump is a space-saving alternative to many overhung process pumps in upstream and downstream services.

... Read more Read less- Single stage, radially vaned, vertical in-line overhung pump according to ISO 13709/API 610 OH3 design recommendations with separate bearing housing as well as OH4 rigidly coupled (WMA)

- Replaceable single channel diffuser can be easily changed for future system requirements

- Straight vaned, low NSS impeller

- Proven OH3 bearing housing design, patented oil circulation with pump ring and flinger, shaft stiffness according to API requirements

- Flowserve

- Hydraulic Institute

- ISO 13709 / API 610

- ISO 21049 / API 682 seal chamber and seal flush plans

- Flows to 45 m3/h (200 gpm)

- Heads to 220 m (725 ft) for single stage design

- Heads to 440 m (1455 ft) for two stage design

- Pressures to 60 bar (870 psi)

- Temperatures -46°C (-51°F) to 260°C (500°F)

Size Range: 2 designs (single stage, double stage) 80 hydraulic designs (8 impeller diameter and 10 different vane hight combinations)

HWMA

single stage HWMA (OH3)

HWMA2

double stage HWMA (OH3)

WMA

single stage HWM (OH4)

WMA2

double stage (OH4)

HWMA-I

Inducer