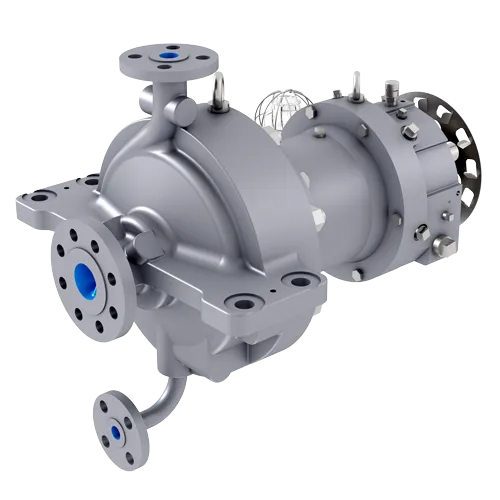

The HPX-Mag sealless pump is based on the proven Flowserve HPX API 610 process pump. It is a horizontal, overhung, single-stage, radially split, end-suction, top-discharge, centerline-mounted pump with a high-efficiency magnetic coupling. This versatile pump provides outstanding leakage protection and can handle the high pressures, temperatures and aggressive/toxic media often found in the oil and gas and hydrocarbon industries. The HPX-Mag magnetic drive pump is in full compliance with the API 685 standard.

- Robust construction meets or exceeds API 685 requirements, ensuring zero emissions in difficult-to-seal, toxic, aggressive and flammable liquids.

- Hermetically sealed design eliminates the need for mechanical seals and external flushing systems.

- Dynamic thrust-balancing system limits vibration and assures smooth operation over a wide flow range.

- Increased mean time between maintenance (MTBM) reduces downtime and maintenance costs.

- Back pullout design simplifies maintenance activities and reduces labor costs.

- Extensive hydraulic coverage enables precise selection for the highest operating efficiency.

- Parts interchangeability with HPX API 610 pump reduces parts inventory and carrying costs.

API 685 2nd edition

Flows to: 1000 m3/h

Heads to: 300 m

Pressures to: 42 barg MAWP

Temperatures: 29°C to 300°C (84°F to 572°F)

Viscosity: 0.2 to 300 cP

Sizes: 1 to 6 in discharge; 7 to 15 in impeller

Pressure class: ASME #300

Materials: S6, C6, A8, D1, and D2

End-Top