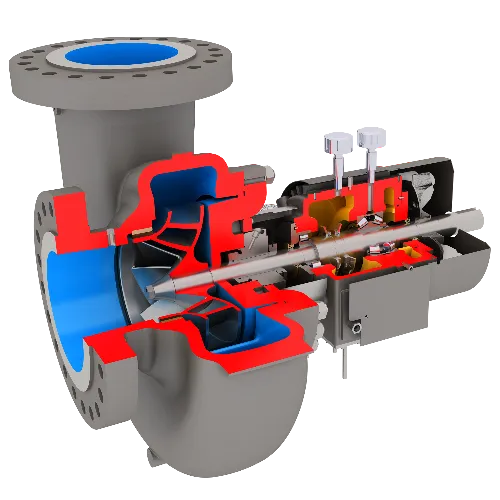

The Flowserve HHPX pump is an end-suction, single-stage, radially split pump designed for high suction pressure seawater reverse osmosis (SWRO) desalination applications, such as energy recovery device (ERD) boosters. It is specially designed to deliver increased efficiency and easy maintenance, helping desalination plants lower energy and maintenance costs.

... Read more Read less- True back pullout design

- Mechanical seal with low resultant seal chamber pressure

- Single or dual volute, depending on the flow rate

- High suction pressure design

- Fan-cooled bearings are oil lubricated

- Fully shrouded, precision-cast impellers and new optimized volute hydraulic passageways

- Non-metallic wear rings

- Flows to 1,800 m³/h (7,930 gpm)

- Heads to 350 m (1,100 ft)

- Pressures to 90 bar (1,305 psi)

- Temperatures to 50°C (122°F)

Sizes: DN 200 to 350 (8 to 14 in)

Pressure class: PN 90 (1,305 psi)

Materials:

- Super-duplex (A890, Grade 5A; PREN ≥ 40)

- Optional Alloy 885 (PREN ≤ 40)