Product Brand

Flowserve Type

Nuclear Products SubType

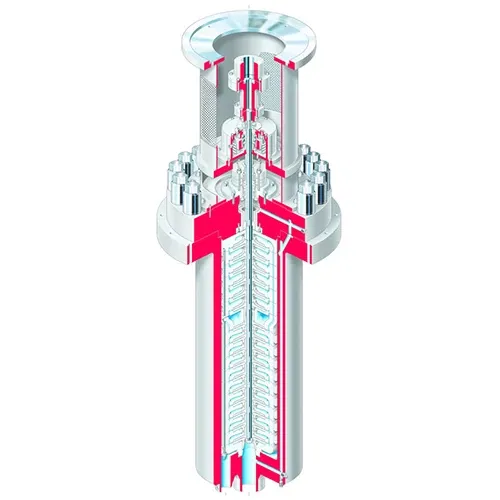

Nuclear Pumps- Suction and discharge connections meet AREVA piping requirements.

- Outer casing is designed for full working pressure and meets all pressure boundary requirements for pump equipment.

- Inner assembly has an internal crossover that reduces hydraulic thrust and increases bearing life.

- Standard cartridge seal reduces maintenance time and man-rem exposure associated with change out.

- Optional bearing housing mounted in the motor stand permits the use of standard electric motors without thrust bearings.

- Four-piece spacer coupling allows maintenance to bearings and mechanical seal without removal of the electric motor.

ASME Section III, Class 2 and 3

- Flows to 60 m3/h (265 gpm)

- Heads to 2000 m (6560 ft)

- Pressures to 235 bar (3410 psi)

- Temperatures to 100°C (212°F)

- Speeds to 3600 rpm

Size Range: 2" to 4" discharge

Vertical multistage barrel

Online Tools