Products Catalog

We offer the world’s largest portfolio of proven high-performance flow control systems, backed by the ongoing development of industry-leading innovations.

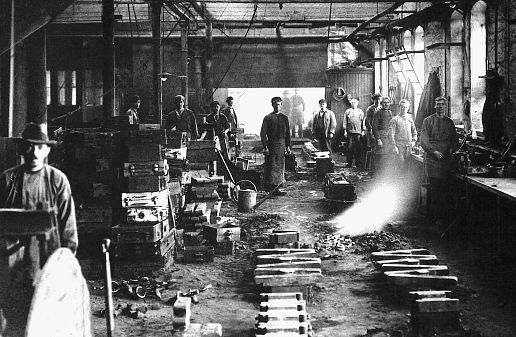

With a heritage of expertise that dates back to the 18th century, Flowserve manufactures and services solutions for the toughest and most critical flow management challenges. Explore this online catalog to find solutions that will enhance the quality, efficiency, reliability, safety and profitability of your operation.

We´re sorry about this 404 error

We couldn’t find what you´re looking for...Try again with different terms or check one of these resources:

PRODUCTS CATALOG

Trying to determine which product and technologies are best for your process?

DOCUMENTS & MANUALS

Looking for brochures, data sheets, guides and other technical resources?

SERVICE CAPABILITIES

Choosing a service to drive greater operational and equipment efficiencies?